Overview

Striker

This style may not reveal (strike to) its target color until fired.

Reactive Potential

Glass in this style produced prior to 4/29/16 contains a small amount of lead.

Contains: Lead (Pb)

May React With: Selenium (Se) / Sulfur (S)

Reactive Potential

Glass in this style produced after 4/29/16 does not contain lead.

Non-reactive. Neutral.

Forms of Glass

Sheet Glass (-0030, -0050), Frit (-0001, -0002, -0003, -0008) and Rod (-0576)

Detailed Information

About 000243 Sheet Glass

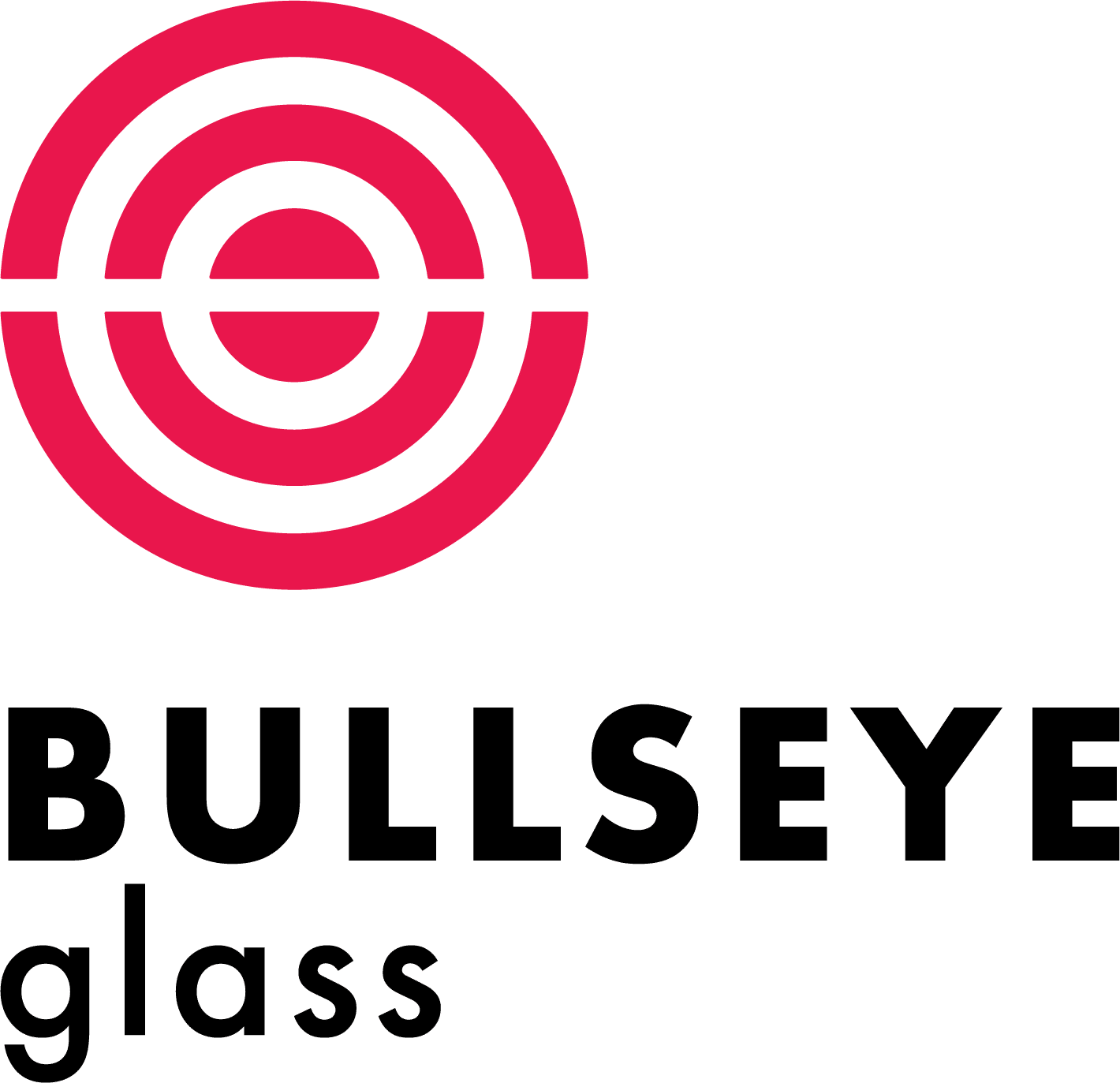

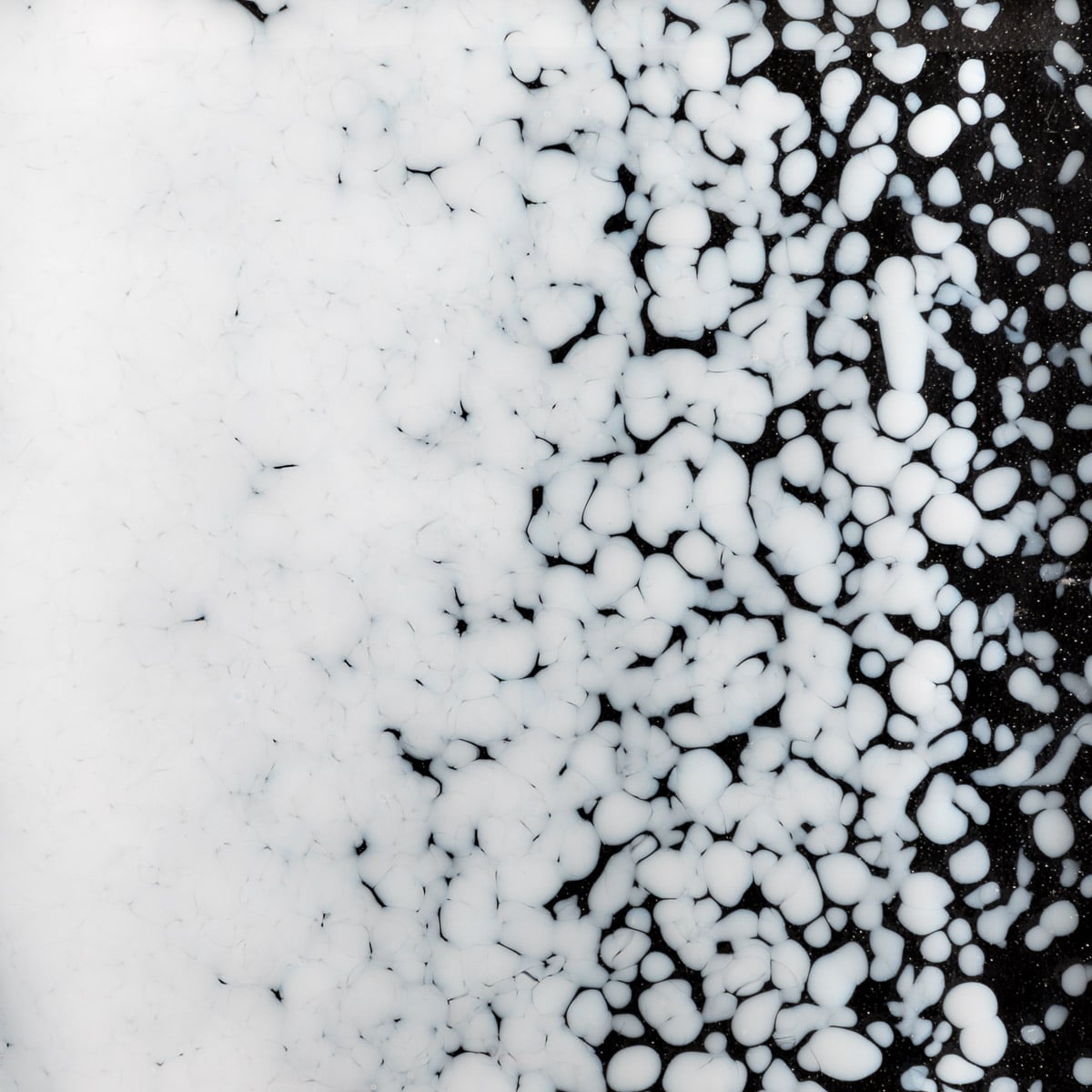

Cold Characteristics

May appear mostly clear with patches of thin milky white.

Working Notes

Opalizes upon firing. Consistent color, thin milky white. Color may become slightly streaky and transparent with excessive heatwork.

Bullseye Compatible.

Production Note

Glass in this style produced prior to 4/29/16 contains a small amount of lead, which may react with Selenium, Sulfur.

About 000243 Frit

See sheet glass notes on this style.

About 000243 Rod

Cold Characteristics

(Deceptively) clear or clear with a white struck streak running lengthwise down the middle of the rod.

Working Notes

Torch: 000243-0576 can strike to a transparent white with stone like qualities similar to quartz.

Generally speaking, the heat required to form a bead leaves the glass unstruck and clear. This glass strikes as it cools, rather than when it is heated.

Here is a series of steps that can make the striking process more efficient.

- Make a bead as usual in a neutral flame.

- Once the bead is formed, cool it (still in the flame, but farther away from the nozzle & flash it in an out of the flame). As the glass cools to a point where it is no longer moving or slumping on the mandrel, turn off the oxygen and hold the bead in the propane (fuel) flame while still rotating the mandrel. Do this until carbon collects on the glass (not just the mandrel). The purpose is not to actually carbonize or reduce the glass but simply to keep it at a cool, consistent temperature throughout the piece.

- Turn the oxygen back on and ease the bead into the neutral flame from the tip of the flame (farthest from the nozzle).

- Reheat the glass and bring it to a slightly molten state while keeping it cool enough to retain its shape. The carbon will burn away. At this point, briefly remove the bead from the flame. Looking closely at the bead, it should start to take on a hazy appearance with a yellow tint which is the glass beginning to strike. The bead may need a little more heat, just to equalize the temperature of the glass and to keep it warm as it gets put into a kiln for annealing. This process holds the glass in the appropriate striking zone, and is slightly unusual for many torchworking styles. This approach may not be necessary if the style of torchwork being done involves holding the glass at cooler temperatures over a longer period of time (like some sculptural work).

Kiln: Opacity may vary upon firing, as the core may not strike completely. Expect variation. Other In making components for kilnforming, it is not necessary to strike the glass in the flame because it will strike in the subsequent kilnforming processes.

On a similar note, 000243-0576 that has been struck to a translucent white in a kiln may change back to clear if worked in the flame. It is possible to strike portions of the 000243-0576 to translucent white and leave some portions clear within the same piece. Continued work in the flame on a piece that is already opalized can “chase” the translucent white color from the molten area and concentrate it in the cooler area within a single piece.