Overview

Striker

This style may not reveal (strike to) its target color until fired.

Reactive Potential

Contains: Sulfur (S) / Selenium (Se)

May React With: Copper (Cu), Lead (Pb), and Silver (Ag)

Forms of Glass

Sheet Glass (-0030, -0050), Frit (-0001, -0002, -0003, -0008), Rod (-0576), and Stringer (-0107, -0272)

Detailed Information

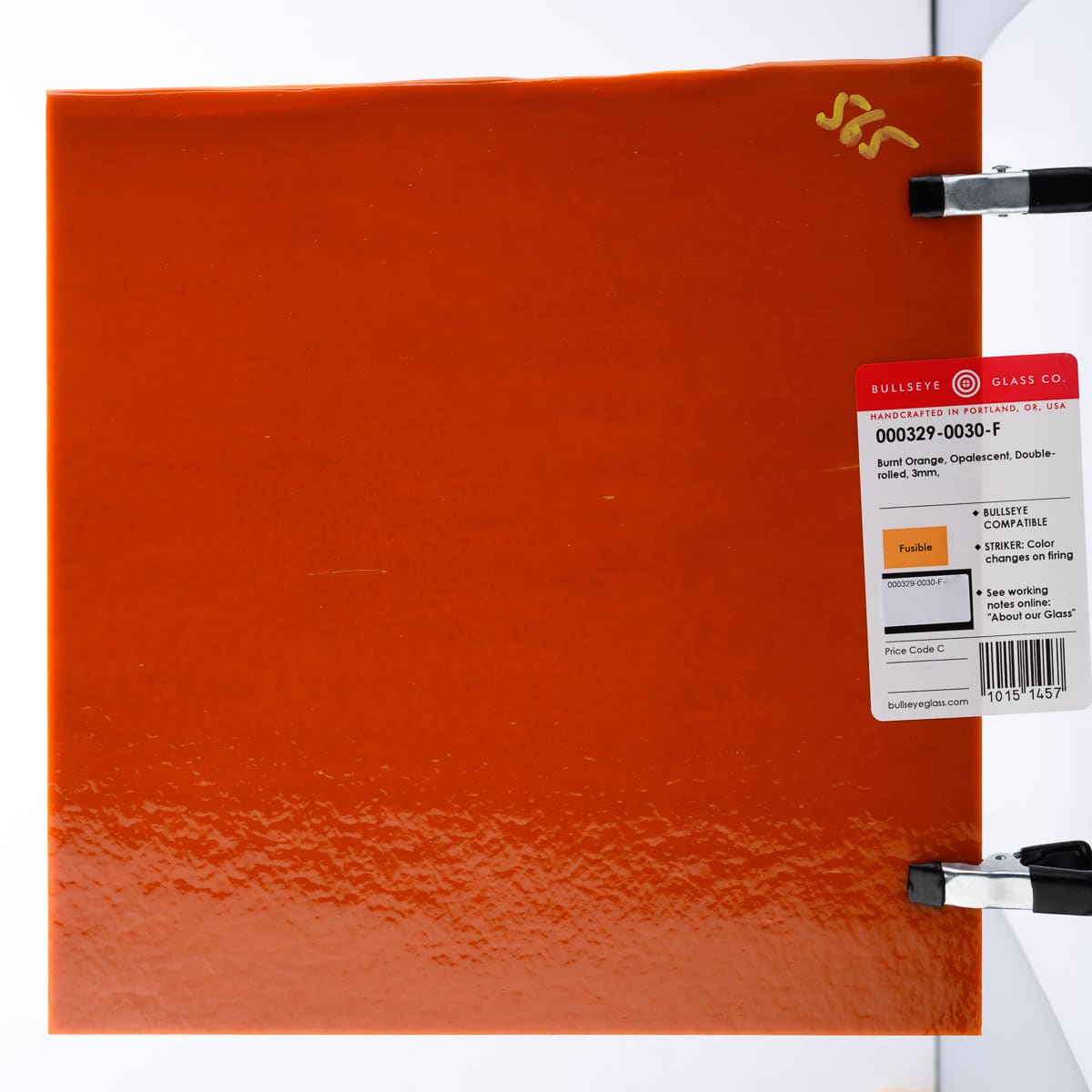

About 000329 Sheet Glass

Cold Characteristics

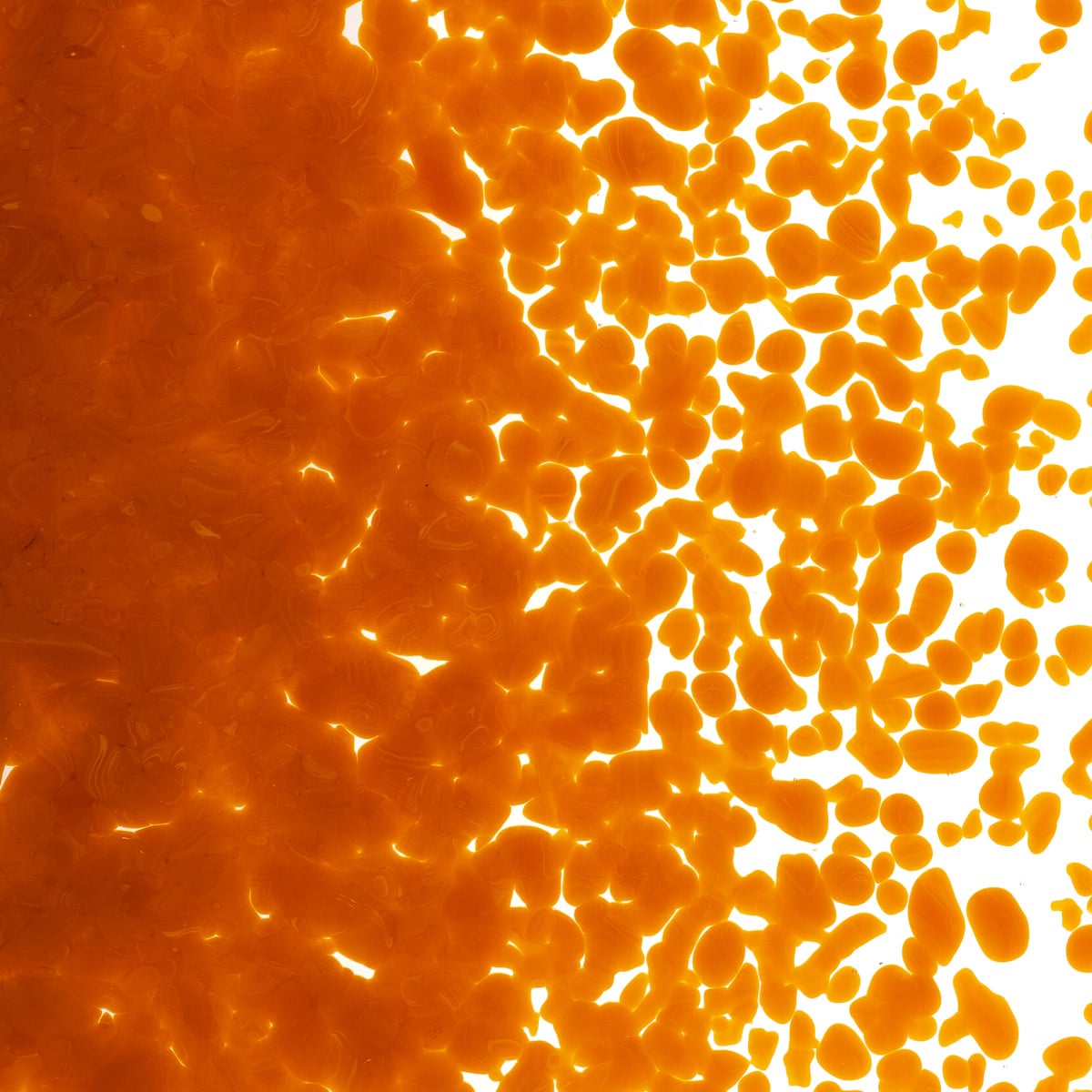

Opalescent. Slight small mottle and orange-peel texture.

Working Notes

At full fuse and capped with clear glass, the mottling may remain but become faint in transmitted light. Lighter wisps may appear in reflected light. When uncapped, the mottling tends to even out and the color becomes more consistent and even.

This style is not suitable for kilncasting because it can become incompatible when held at high temperatures for an extended period. It may also become incompatible in instances where processes exceed the parameters of the test for compatibility. Testing recommended when heatwork exceeds these parameters.

Bullseye Compatible.

About 000329 Frit

Working Notes

This style is not suitable for kilncasting because it can become incompatible when held at high temperatures for an extended period. It may also become incompatible in instances where processes exceed the parameters of the test for compatibility. Testing recommended when heatwork exceeds these parameters.

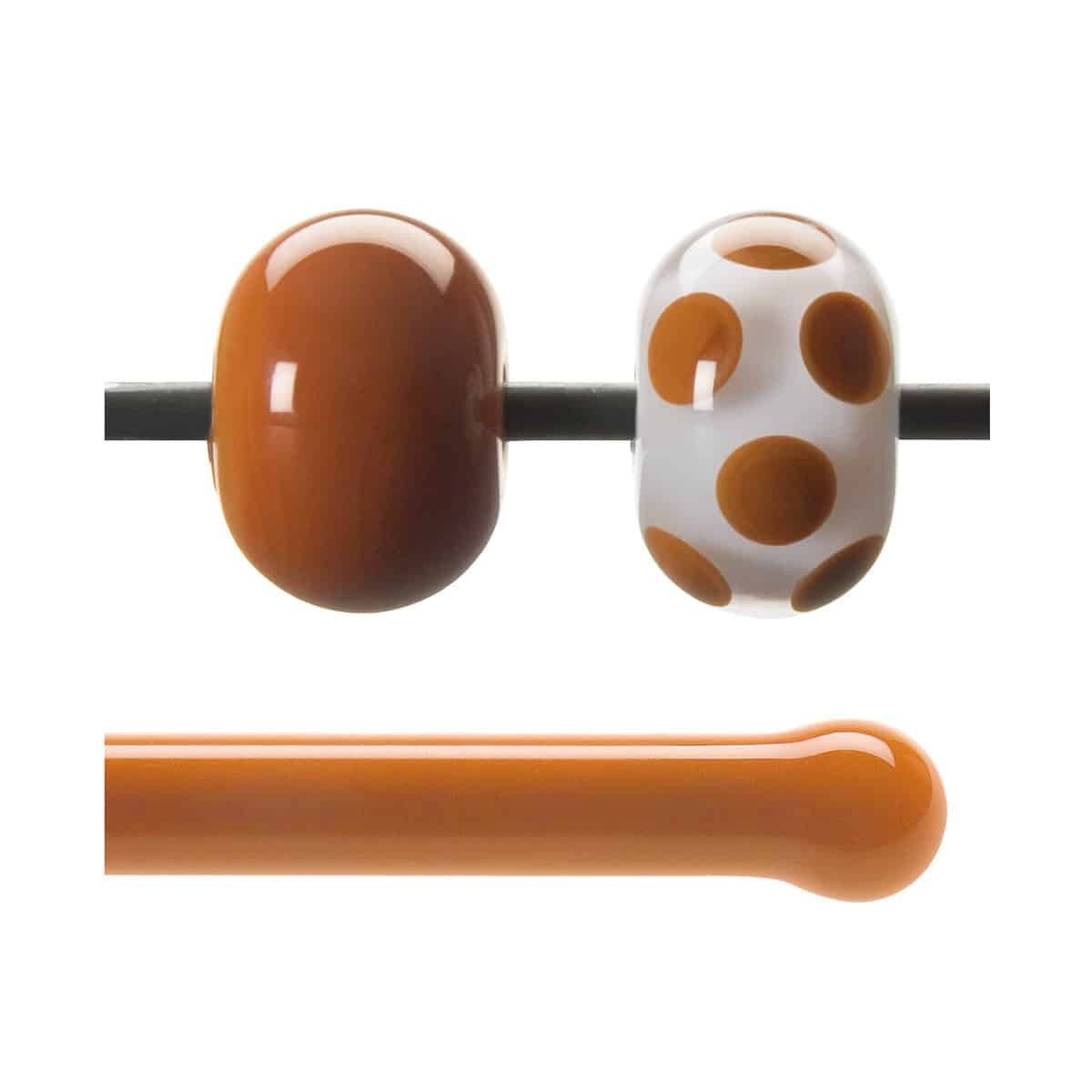

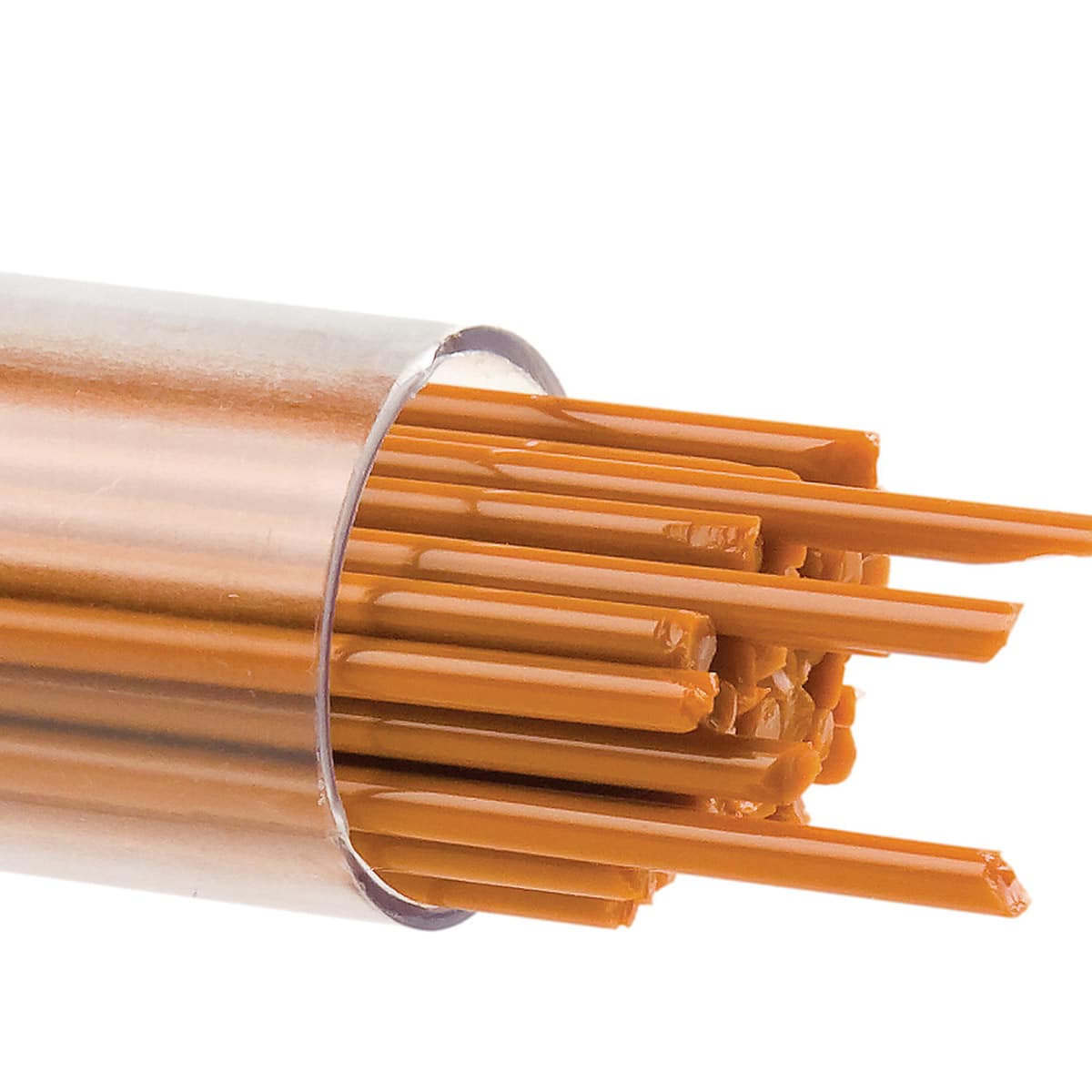

About 000329 Rod

Cold Characteristics

Opaque.

Working Notes

This style is not suitable for kilncasting because it can become incompatible when held at high temperatures for an extended period. It may also become incompatible in instances where processes exceed the parameters of the test for compatibility. Testing recommended when heatwork exceeds these parameters.

Torch: A range of color can be achieved by variations in heatwork within a single piece.

Kiln: Lighter color and greater opacity than in sheet glass form. Slight variation in color with different production runs.

Other: Flameworked color is a shade darker than the cold rod.

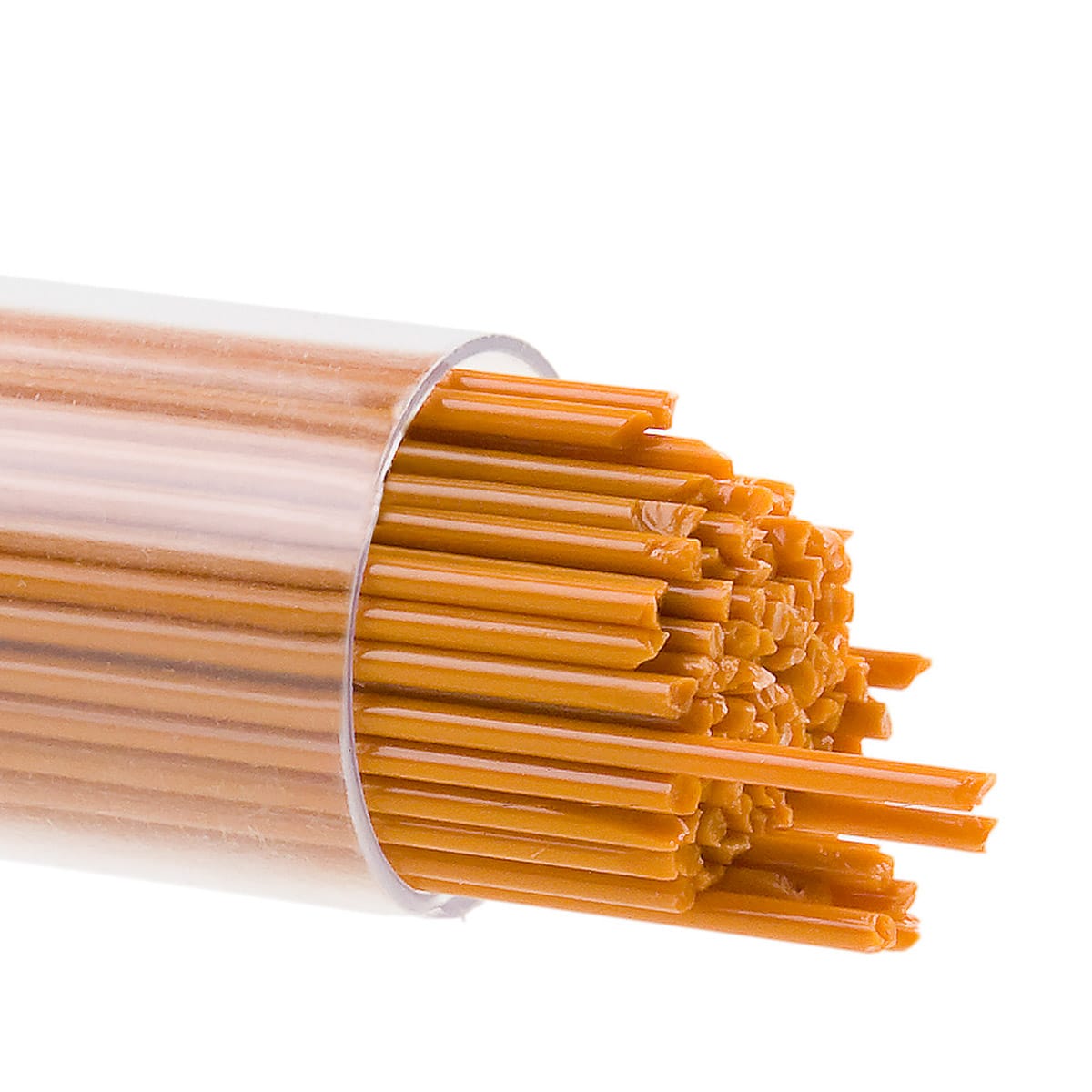

About 000329 Stringer

Working Notes

This style is not suitable for kilncasting because it can become incompatible when held at high temperatures for an extended period. It may also become incompatible in instances where processes exceed the parameters of the test for compatibility. Testing recommended when heatwork exceeds these parameters.