Creating a Reliable Shelf System

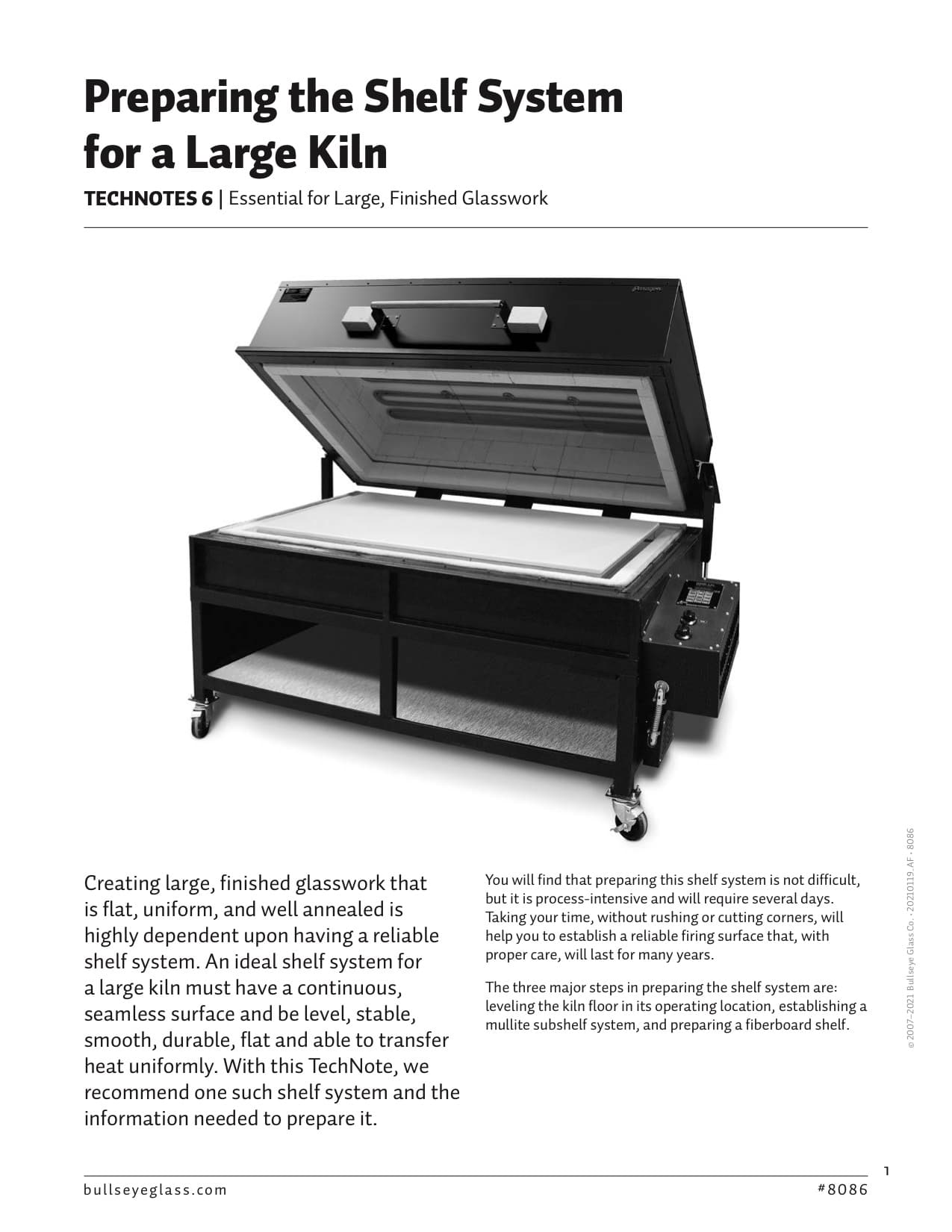

Creating large, finished glasswork that is flat, uniform, and well annealed is highly dependent upon having a reliable shelf system. An ideal shelf system for a large kiln must have a continuous, seamless surface and be level, stable, smooth, durable, flat and able to transfer heat uniformly. With this TechNote, we recommend one such shelf system and the information needed to prepare it.

You will find that preparing this shelf system is not difficult, but it is process-intensive and will require several days. Taking your time, without rushing or cutting corners, will help you to establish a reliable firing surface that, with proper care, will last for many years.

The three major steps in preparing the shelf system are: leveling the kiln floor in its operating location, establishing a mullite subshelf system, and preparing a fiberboard shelf.

Step 1: Leveling the Kiln in its Operating Location

Ideally, you will be able to position the kiln in a level operating location.

Once the kiln is positioned, you will need to determine how level its floor is. Do this by placing a level on the kiln floor, taking readings from side to side, front to back, and corner to corner (Figure 2).

If your level is short, set it on a long straightedge to evaluate a larger span. If you find that your kiln floor is not level, you will need to make adjustments. Some slight leveling can be accomplished later, by positioning shims under sections of the mullite subshelf (Step 2). But if one side of the kiln floor is 0.125˝ (3 mm) lower than the other, the kiln itself should be leveled. In general, for the sake of stability, it is better to level the kiln than to rely on shims.