Hot glass will stick to most ceramic surfaces and crack as it cools, unless prevented by a separator like Bullseye Shelf Primer. Careful application of our primer to shelves and molds will result in smooth, effective firing surfaces.

Mixing

Mix one part shelf primer powder to five parts (by volume) water. Stir the mix frequently during application.

Assuming a 20˝ x 20˝ (51 × 51cm) shelf, one pound (454 grams) of dry shelf primer will make enough mix to prepare about 32 shelves with the required five coats per shelf.

Application

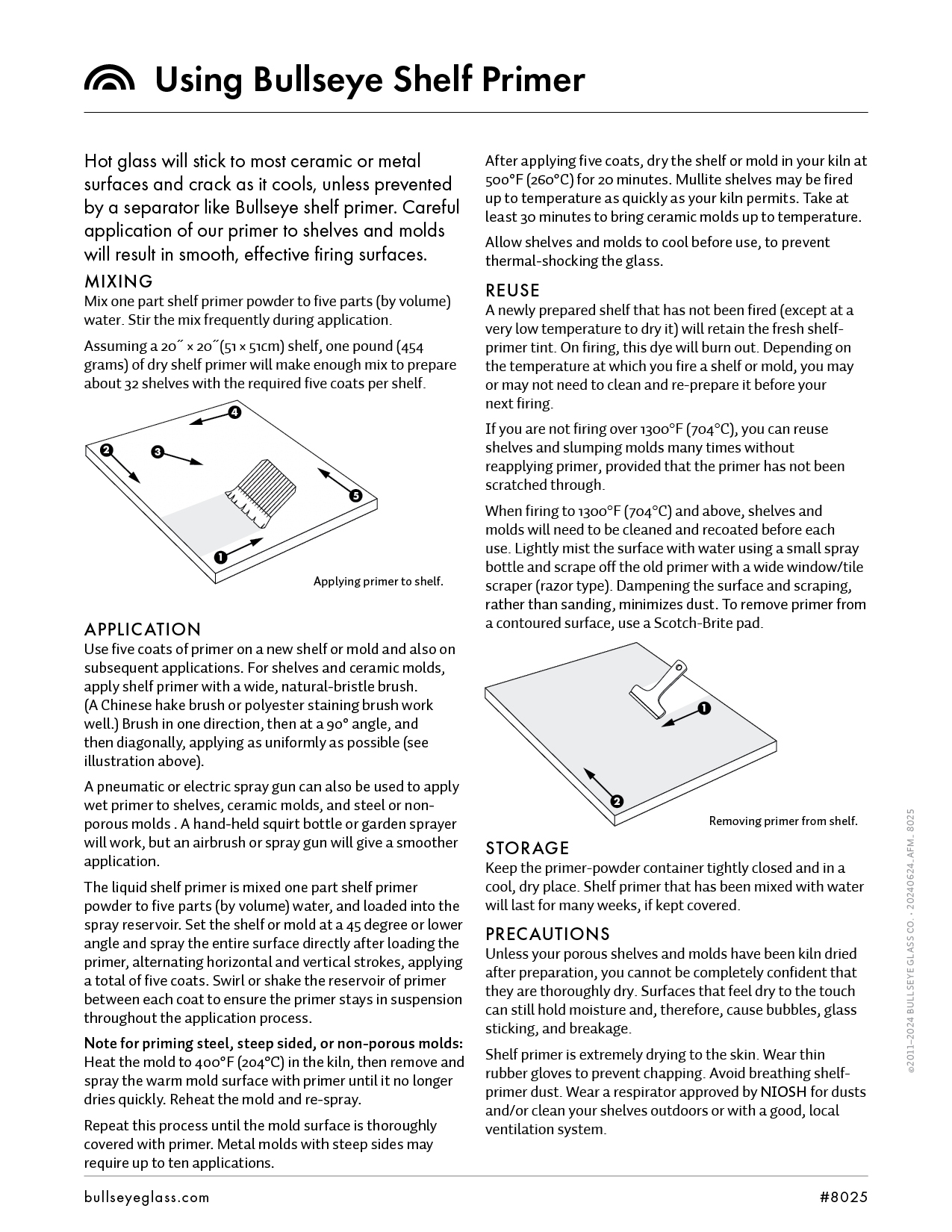

Use five coats of primer on a new shelf or mold and also on subsequent applications. For shelves and ceramic molds, apply shelf primer with a wide, natural-bristle brush.

(A Chinese hake brush or polyester staining brush work well.) Brush in one direction, then at a 90° angle, and then diagonally, applying as uniformly as possible (see illustration above).

A pneumatic or electric spray gun can also be used to apply wet primer to shelves, ceramic molds, and steel or non-porous molds . A hand-held squirt bottle or garden sprayer will work, but an airbrush or spray gun will give a smoother application.

The liquid shelf primer is mixed one part shelf primer powder to five parts (by volume) water, and loaded into the spray reservoir. Set the shelf or mold at a 45 degree or lower angle and spray the entire surface directly after loading the primer, alternating horizontal and vertical strokes, applying a total of five coats. Swirl or shake the reservoir of primer between each coat to ensure the primer stays in suspension throughout the application process.

Note for priming steel, steep sided, or non-porous molds: Heat the mold to 400°F (204°C) in the kiln, then remove and spray the warm mold surface with primer until it no longer dries quickly. Reheat the mold and re-spray.

Repeat this process until the mold surface is thoroughly covered with primer. Metal molds with steep sides may require up to ten applications.

After applying five coats, dry the shelf or mold in your kiln at 500°F (260°C) for 20 minutes. Mullite shelves may be fired up to temperature as quickly as your kiln permits. Take at least 30 minutes to bring ceramic molds up to temperature.

Allow shelves and molds to cool before use, to prevent thermal-shocking the glass.

Reuse

A newly prepared shelf that has not been fired (except at a very low temperature to dry it) will retain the fresh shelf-primer tint. On firing, this dye will burn out. Depending on the temperature at which you fire a shelf or mold, you may or may not need to clean and re-prepare it before your

next firing.

If you are not firing over 1300°F (704°C), you can reuse shelves and slumping molds many times without

reapplying primer, provided that the primer has not been scratched through.

When firing to 1300°F (704°C) and above, shelves and molds will need to be cleaned and recoated before each use. Lightly mist the surface with water using a small spray bottle and scrape off the old primer with a wide window/tile scraper (razor type). Dampening the surface and scraping, rather than sanding, minimizes dust. To remove primer from a contoured surface, use a Scotch-Brite pad.

Storage

Keep the primer-powder container tightly closed and in a cool, dry place. Shelf primer that has been mixed with water will last for many weeks, if kept covered.

Precautions

Unless your porous shelves and molds have been kiln dried after preparation, you cannot be completely confident that they are thoroughly dry. Surfaces that feel dry to the touch can still hold moisture and, therefore, cause bubbles, glass sticking, and breakage.

Shelf primer is extremely drying to the skin. Wear thin rubber gloves to prevent chapping.

Avoid breathing shelf-primer dust. Wear a respirator approved by NIOSH for dusts and/or clean your shelves outdoors or with a good, local ventilation system.