When I put it in the kiln, the glass was blue. When I took it out, it was the color of mild steel. When I fire it again, it was blue. What’s going on?

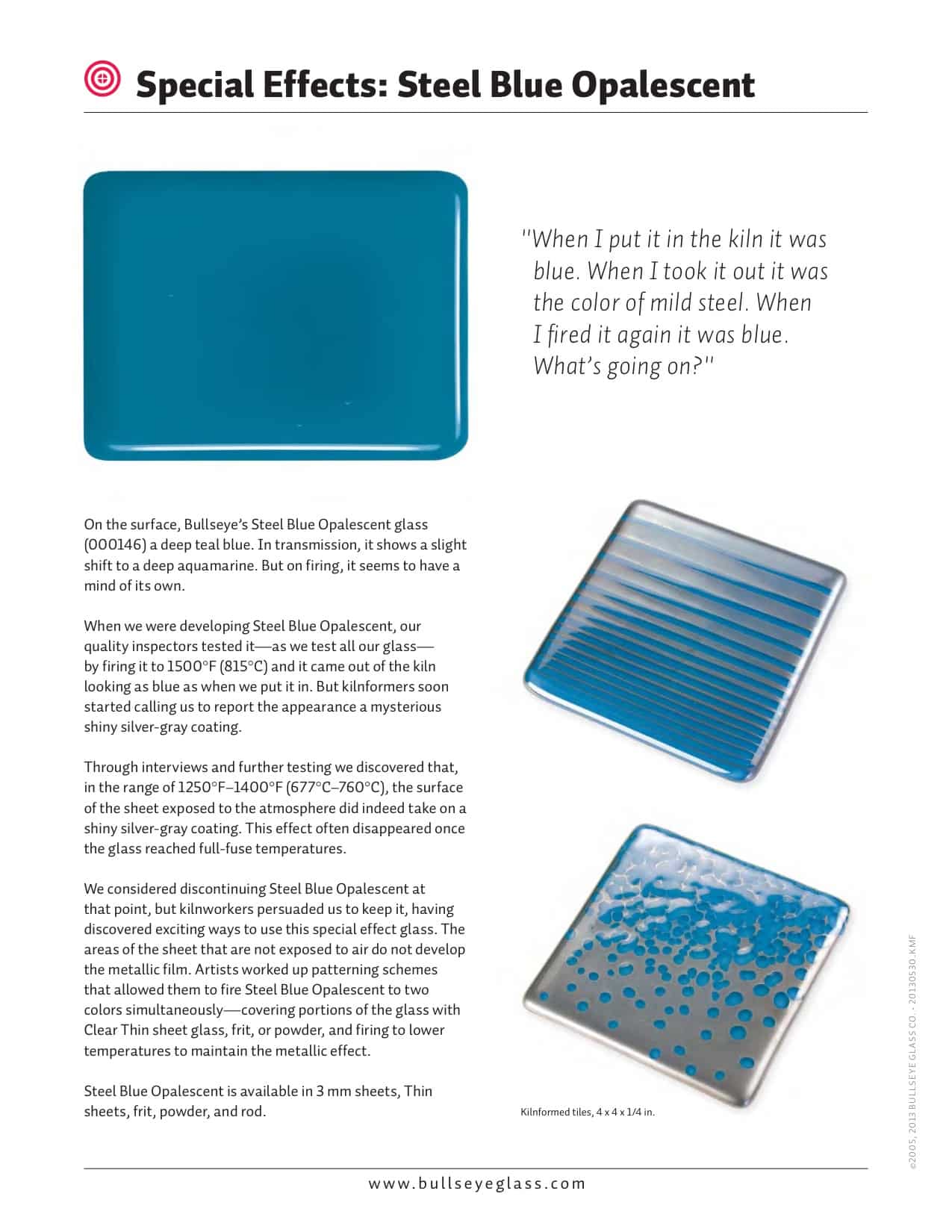

On the surface, Bullseye’s Steel Blue Opalescent glass (000146) is a deep teal blue. In transmission, it shows a slight shift to a deep aquamarine. But on firing, this glass seems to have a mind of its own.

When we were developing Steel Blue Opal, our quality inspectors tested it—as we test all our glass—by firing it to 1500°F (815°C) and it came out of the kiln looking as blue as when we put it in. But kilnformers soon called us to report the appearance a mysterious shiny silver-gray coating.

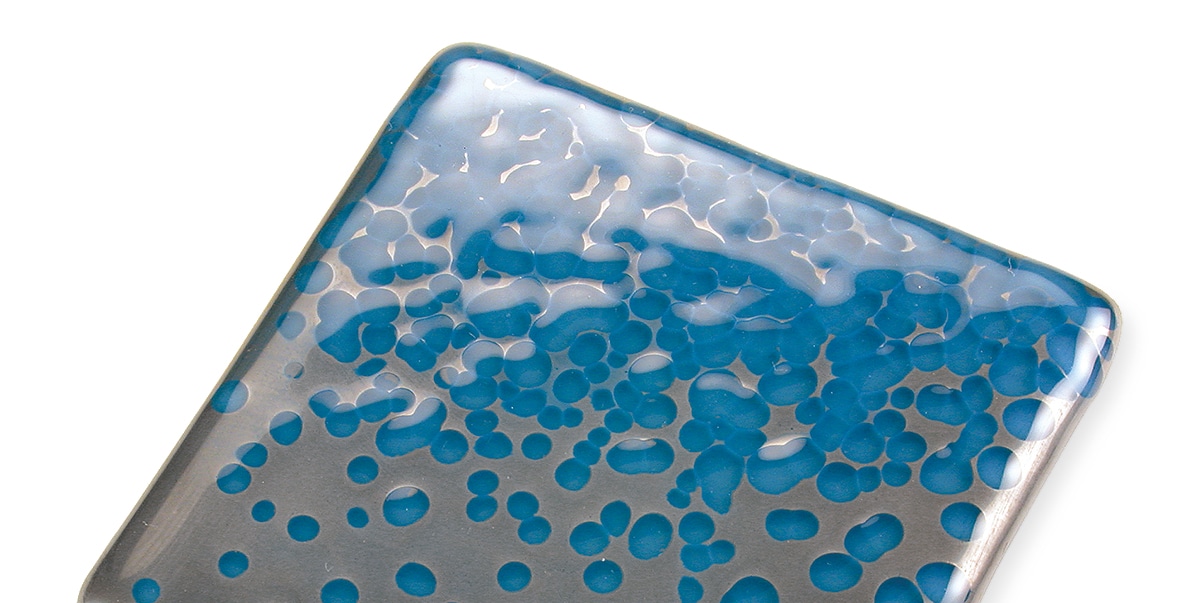

Through interviews and further testing, we discovered that between 1250°F–1425°F (677°C–773°C), the surface of the sheet exposed to the atmosphere did indeed take on a shiny silver-gray coating. This effect often disappeared once the glass reached full-fuse temperatures.

We considered discontinuing Steel Blue Opalescent at that point, but kilnworkers persuaded us to keep it, having discovered exciting ways to use this special effect glass. The areas of the sheet that are not exposed to air do not develop the metallic film. Artists worked up patterning schemes that allowed them to fire Steel Blue Opalescent to two colors simultaneously—covering portions of the glass with Clear Thin sheet glass, frit, or powder, and firing or re-firing to lower temperatures to keep the metallic effect.

Steel Blue Opalescent is available in 3 mm sheets, Thin sheets, frit, powder, and rod.

Although the metallic effect coating is not entirely predictable, we have observed it on pieces fired to a full fuse (1490°F/810°C) as well as within the previously mentioned tack fuse range. If a piece was designed and constructed to achieve the metallic coating, but it did not develop, try a second firing within the range where this effect is more predictable (for example, 1375°F/746°C with a 10-minute hold).

Most forms of Steel Blue Opalescent share this metallic characteristic, though we’ve noticed that powder tends to exhibit this effect (as a dark gray hue) more reliably in the sinter or tack fuse range of 1250–1375°F (677–746°C). With greater heat work, Steel Blue Opalescent Powder often fires with a blue hue, even where exposed.

Learn more about Steel Blue Opalescent, including its reactive potential, in the About Our Glass section of bullseyeglass.com.