Overview

Striker

This style may not reveal (strike to) its target color until fired.

Reactive Potential

Contains: Copper (Cu), Lead (Pb) and Silver (Ag)

May React With: Sulfur (S) / Selenium (Se), and Reactive (000009, 001009, 001019)

Forms of Glass

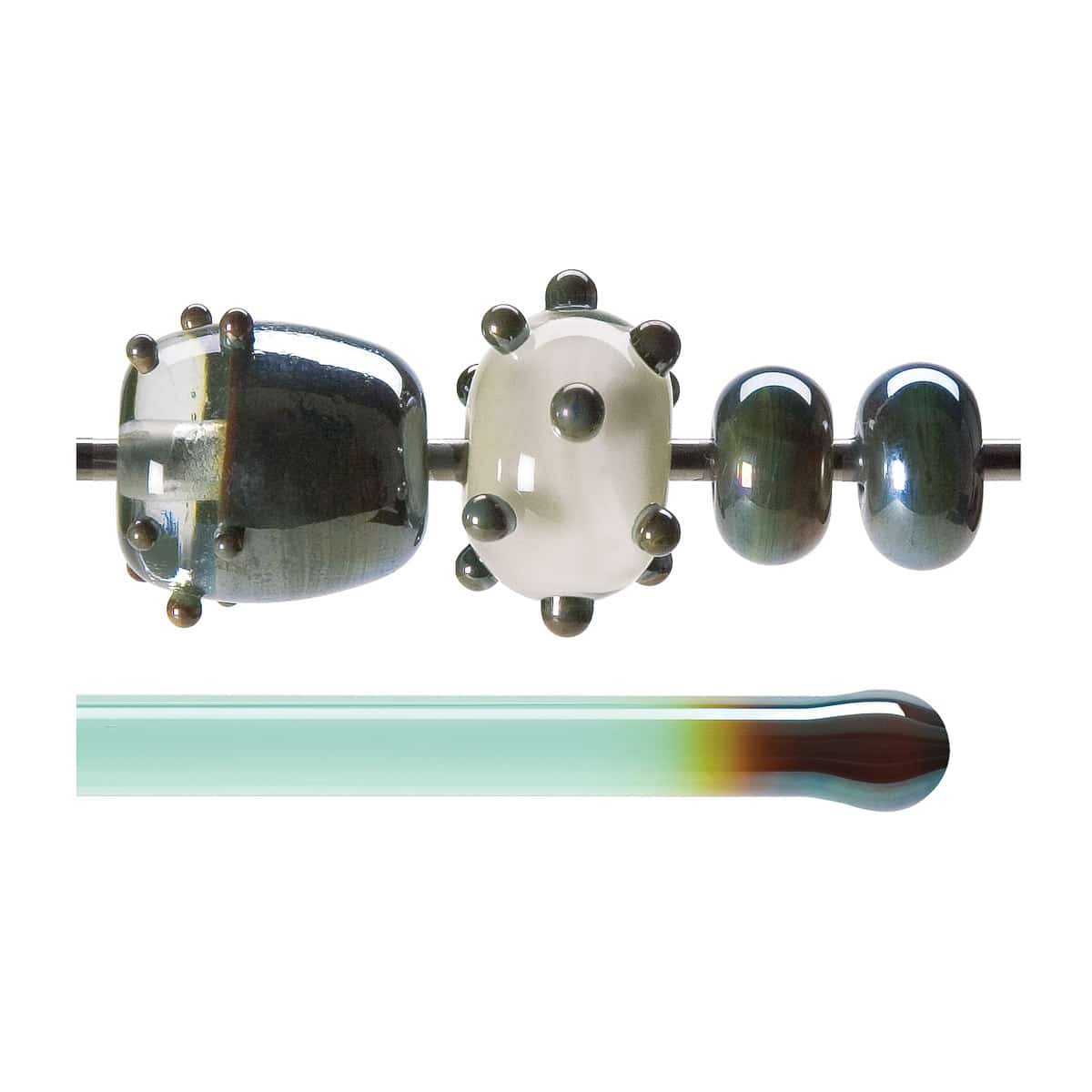

Rod (-0576)

Detailed Information

About 001714 Rod

Cold Characteristics

Pale transparent aqua-green.

Working Notes

Torch: A versatile reducing glass that can develop a metallic sheen and/or opalize to a variegated, putty-like green. These various effects can be achieved by working with 001717-0576 with specific flame chemistry and heat history. Results will depend greatly upon the type of heat and forming methods required.

As 001717-0576 is heated into a gather and wound onto a mandrel, it will opalize on the rod between the gather and the cold glass. If formed hot enough, the bead will remain transparent. When you are ready to develop a metallic sheen, the glass should be relatively cool (no visible heat) and stable on the mandrel. Create a reduction atmosphere by turning the propane (fuel) up and while passing the bead through the flame, watch for the surface of the glass to become metallic. The lustre surface develops readily on cooler glass and can vary greatly depending on the length of time spent in the reduction atmosphere. Once this has happened, the piece should be put into an annealing kiln. This is a finishing step. If the metallic surface is reintroduced to a neutral flame, it will dissipate. It can be brought out again by returning it to a reduction atmosphere.

Often a design will necessitate holding the glass at a warm, stable state (cooler than molten, fluid glass). Under these conditions, 001717-0576 is likely to opalize. Once opalized, 001717-0576 may still be reduced as described above to bring out a metallic sheen, though it takes a little longer to develop. The finished appearance is different because it is backed by the opalized glass. Consider using 001717-0576 for its unique opalized color and work with it in a neutral to oxidizing atmosphere without reduction treatment.

When molten, this glass has a low viscosity, and can be quite soft, which may result in a blurred edge where it meets other glasses. In addition, the process of reducing the glass can cause a metallic sheen over areas of glass immediately adjacent to this style.

Kiln: Not recommended for kilnforming.

Other: 001717-0576 is a relatively heavy glass, and there are 14 rods per pound (compared with 18-20 rods per pound for most other styles). Labeling is encouraged.

Lustre rods are not part of the Bullseye Compatible line for kilnforming and are formulated solely for flameworking with Bullseye rods. We advise labeling all lustre glasses.