The Bullseye Glass Story

~A factory, started by artists to make material for other artists.~

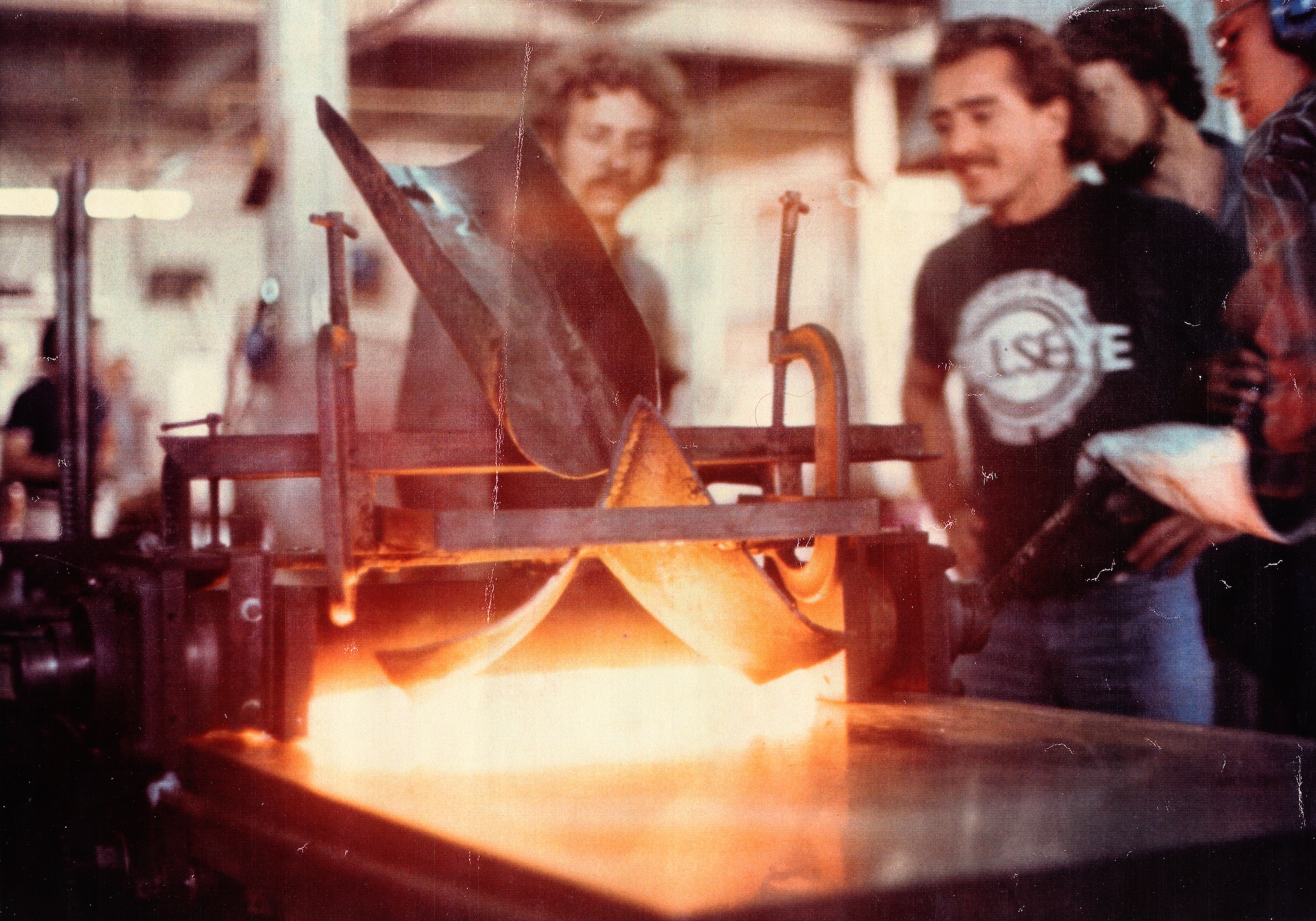

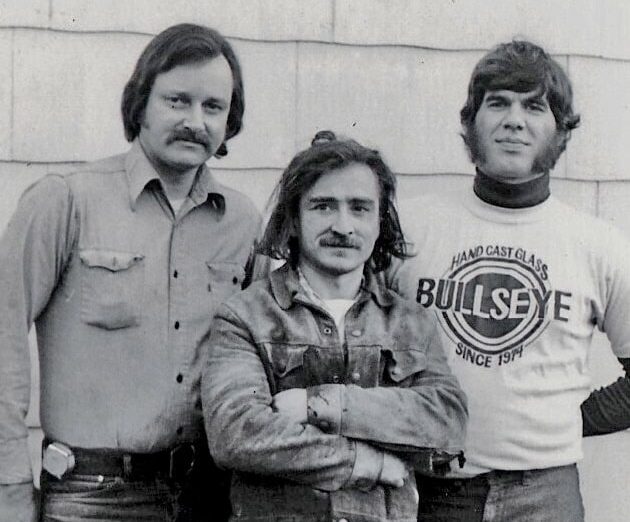

In 1974, three recent art school graduates cobbled together a glass factory in the backyard of a ramshackle house in Portland, Oregon. Resourceful by nature and necessity, they built their factory with scraps repurposed from a shipyard. And, their products—hand-rolled sheets for the stained glass trade—were made from recycled bottle cullet. Shamelessly innovative and unconventional, Bullseye Glass Company was born.

A Chance Encounter

A chance encounter with artist Klaus Moje in 1979 inspired them to do something that had never been done before—something that would change the company’s course and the history of glass art. They produced a palette of tested-compatible glasses for creating works in a kiln.

This reliably fusible glass was an extraordinary product that artists had historically longed for. However, there was a problem—almost no one knew what to do with it. Undaunted, Bullseye embarked on a long-term program of research and education by working hand-in-hand with artists to expand and share the technical, aesthetic, and conceptual possibilities of what we now call “kiln-glass.”

Want to learn more? See the extended version of the Bullseye story by Vitreonics.

Bullseye Today

Nearly five decades later, the Bullseye factory has expanded to cover most of the block around the old house where it all started. While the practice of glass fusing, or kilnforming, has expanded exponentially, Bullseye still produces glass the same way as in 1974—one handmade sheet at a time. At this time, the factory casts up to 1,500 sheets every day, in addition to fusible accessory glasses like powder, frit, ribbon, and stringer. Significantly, Bullseye Glass now ships to countries around the world for makers who create stunningly diverse glassworks.

Passion & Curiosity

Our Research & Education team continues to explore and share new ways of working with this remarkable material. Bullseye Studio, the fabrication arm of Bullseye Glass Co., collaborates with artists, architects, and designers to demonstrate the large-scale potential of kilnformed glass. In like manner, Bullseye Projects champions artists from around the world who work in kilnforming by mounting exhibitions and offering in-depth residencies. The Bullseye Online Store continues to make our materials and favorite tools accessible. And finally, our Bullseye Glass Resource Centers provide classes and Open Studio access to empower anyone to create with color and light.

Whatever your knowledge of glass, or experience level, we’re glad that you found us. Let us help you explore further! After all, Bullseye Glass Co. exists to encourage, inspire, and give you the tools you need to make the world brighter and more colorful through the incredible potential of glass.

Environmental Care & Neighborly Commitment

We have always been concerned about the environment. In 2004, we were honored with an award from the City of Portland for achieving a 60% reduction in our water consumption, the result of our investment in a cooling water recycling system. In 2005, we invested $1.3 million in a cryogenic oxygen system to reduce our use of natural gas and decrease our greenhouse gas emissions by more than 60%. We reinforce that investment every year, spending $250,000 more on oxygen than we would have spent had we continued to use only natural gas. In 2016, we installed an emissions control system at a cost of $1.5 million, allowing us to meet rigorous environmental standards. In 2022, we installed LED lights across our factory and office spaces to conserve electricity.

We love Portland and care for it as our home. Many of our employees live near the Bullseye Factory and Studio in the SE inner city. Encouraged by company incentive programs, 28% ride their bikes to work, while another 15% walk or take public transportation. We are committed, conscientious neighbors who aim to make our city as healthy and vibrant as it can be. To better understand who we are and what we’re about, we encourage everyone to take our virtual factory tour above. And for anyone who wants to experience Bullseye Glass Co. firsthand, we invite you to stop by one of our Resource Centers, or to schedule an in-person tour of the Bullseye Factory.