Overview

Reactive Potential

Contains: Copper (Cu)

May React With: Selenium (Se) / Sulfur (S), Reactive styles (000009, 001009, 001019)

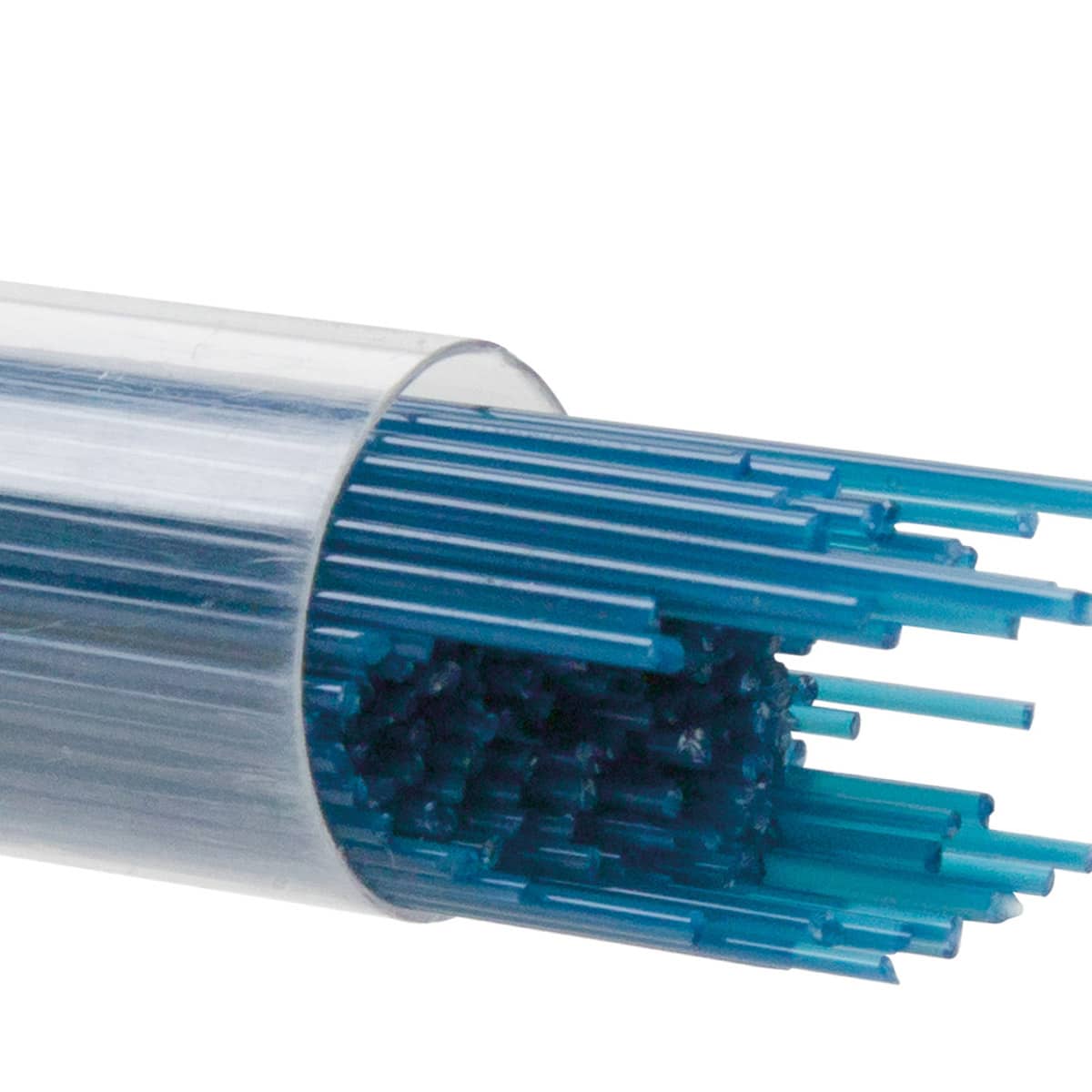

Forms of Glass

Sheet Glass (-0030, -0050), Frit (-0001, -0002, -0003, -0008), Rod (-0576), and Stringer (-0107, -0272)

Detailed Information

About 000146 Sheet Glass

Cold Characteristics

Uniform color.

Working Notes

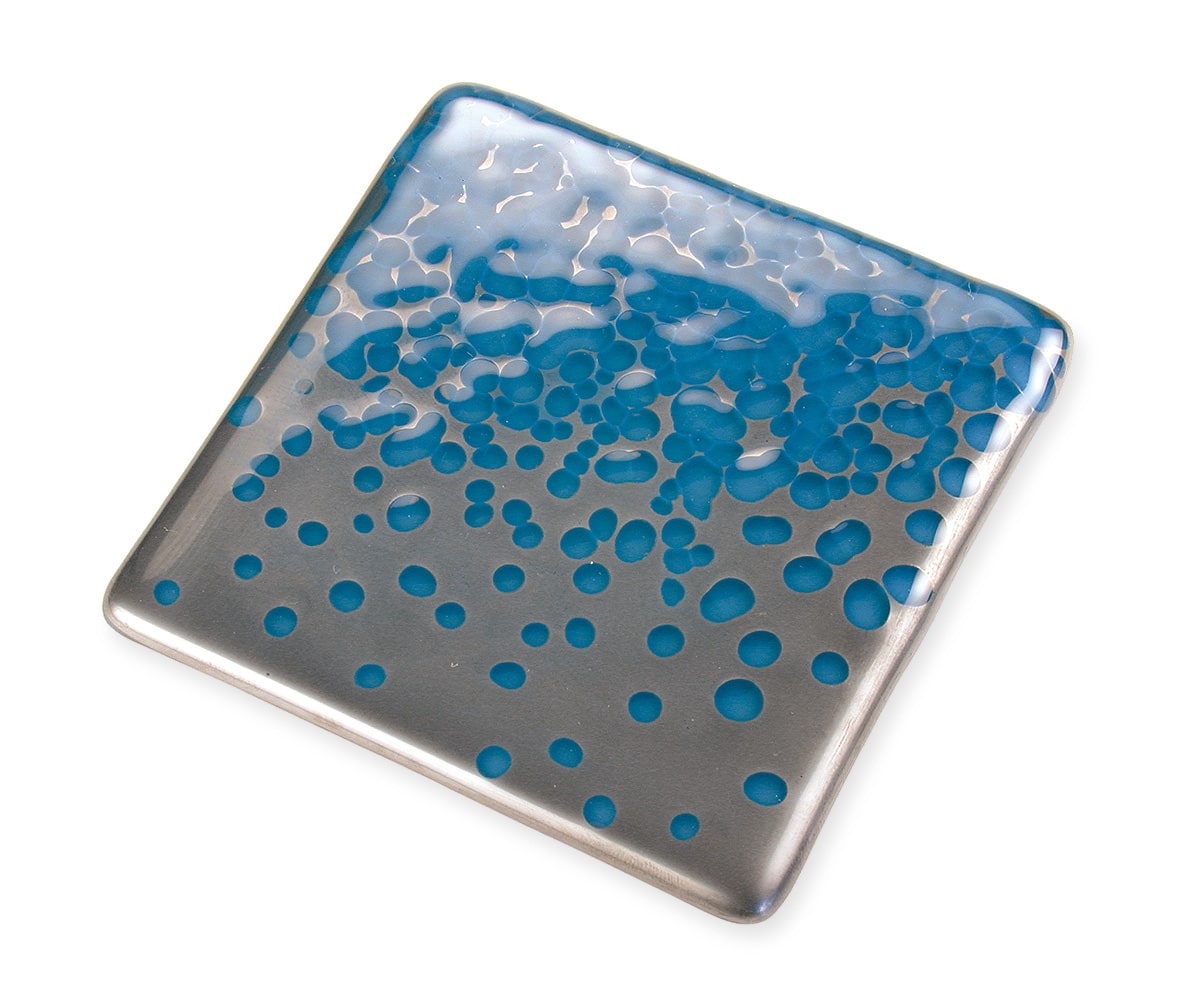

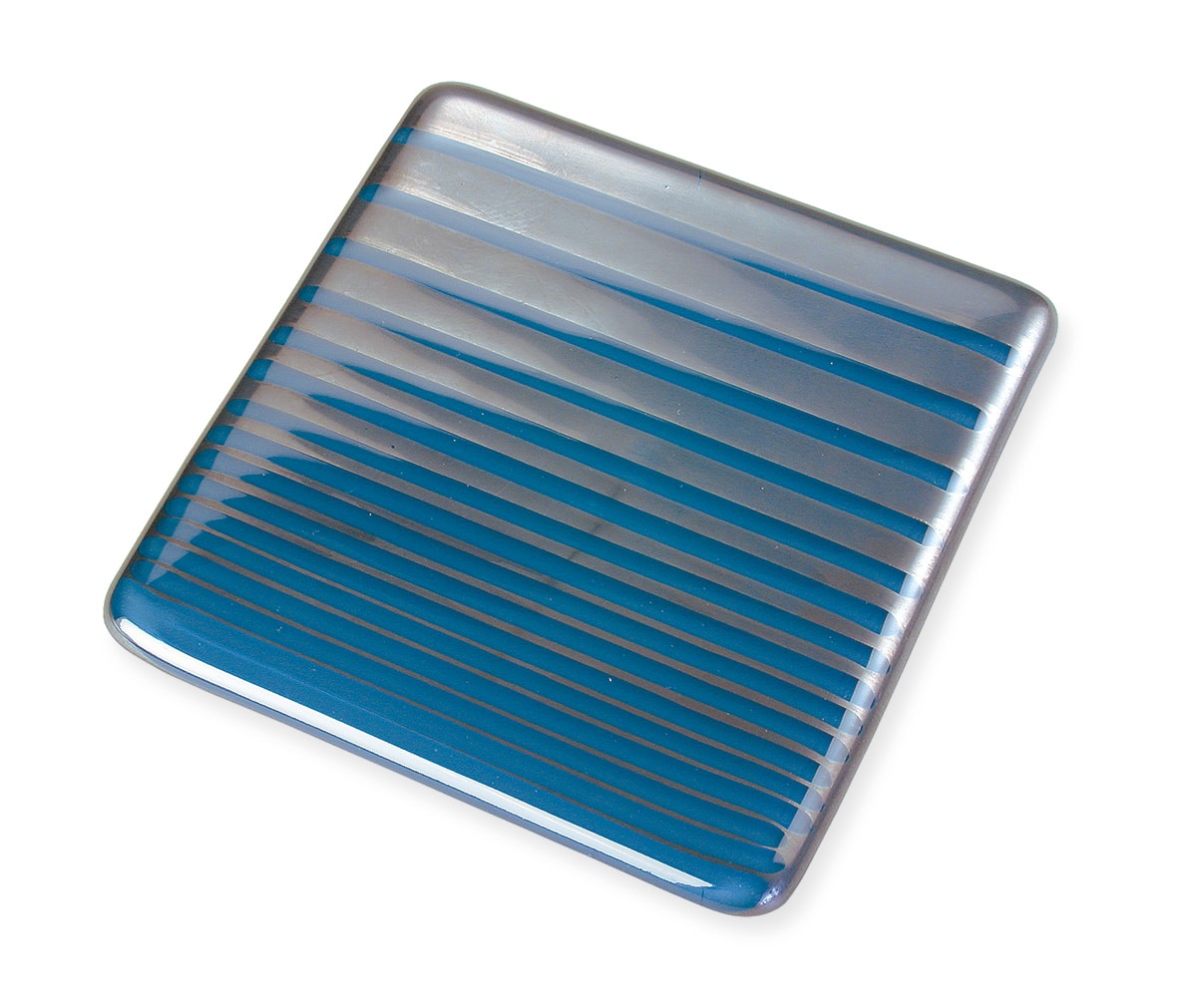

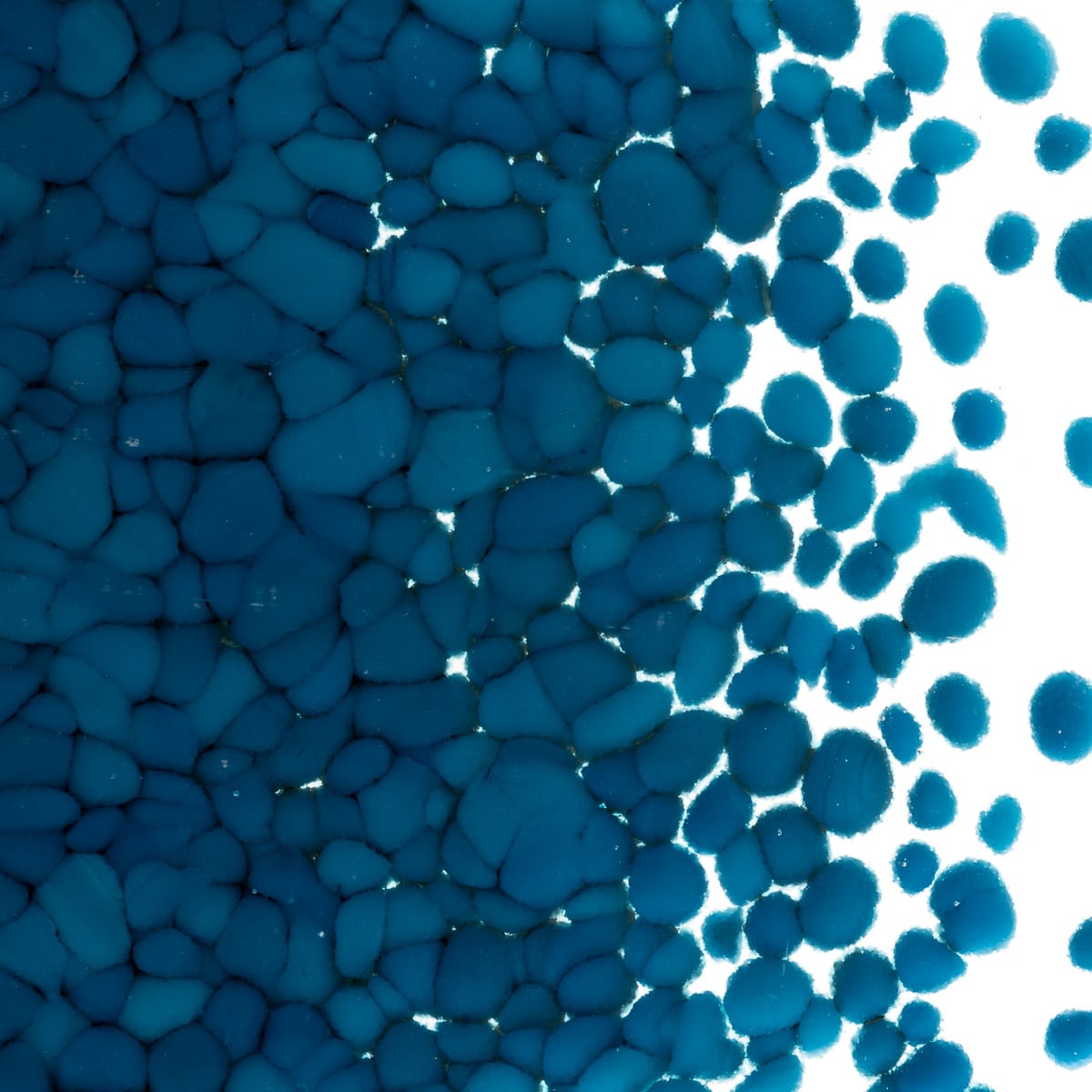

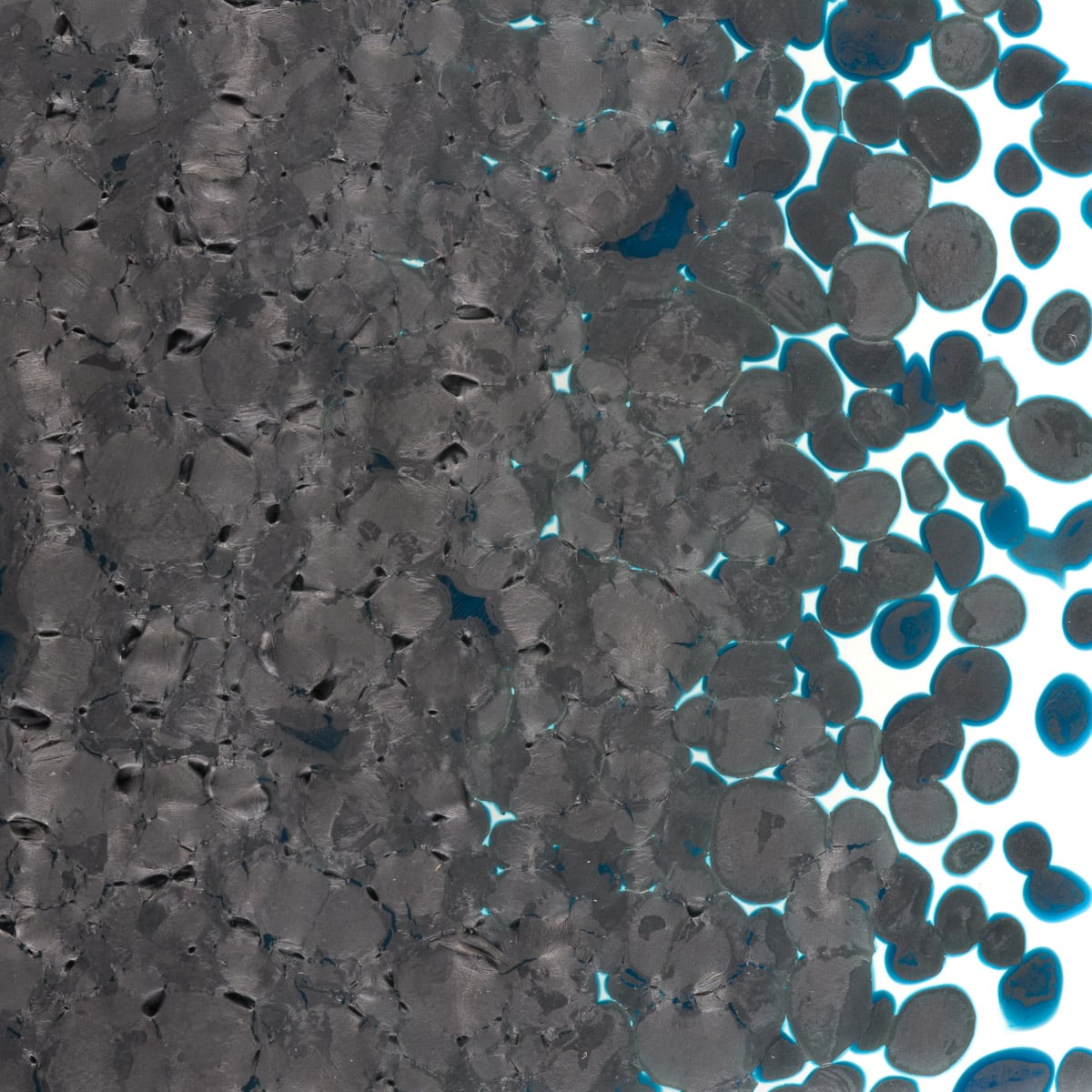

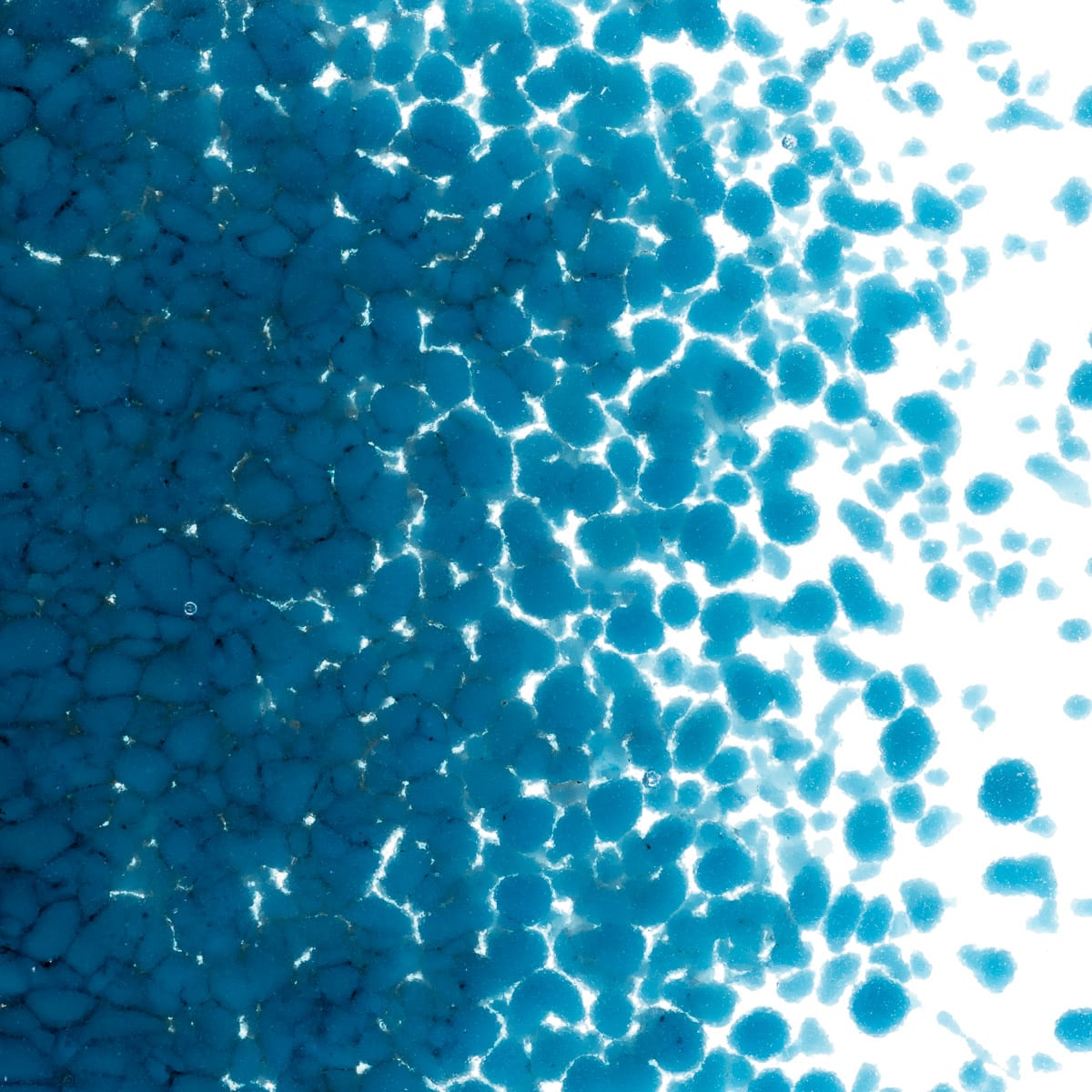

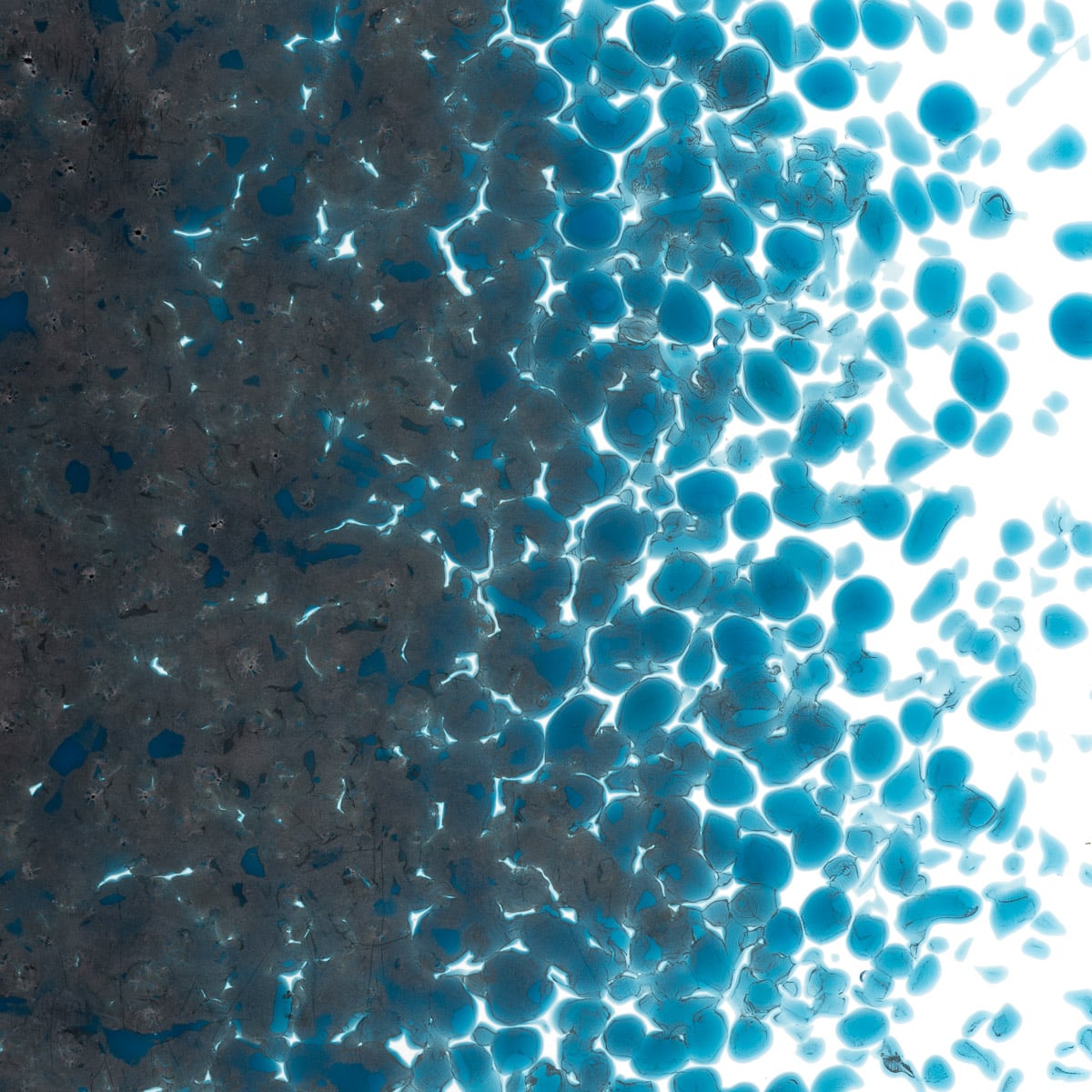

Metallic Finish Note: At tack fusing temperatures, the surface frequently develops a metallic gray film. This usually disappears at full fusing temperatures. To maintain the metallic effect, fire as quickly and low as possible. To learn more about this style, read Special Effects: Steel Blue Opalescent.

applied on top of 0146. Those unexposed

portions did not develop a metallic film.

applied on top of 0146. Those unexposed

portions did not develop a metallic film.

Reaction Note: Dark interface reaction likely with sulfur glasses (for example 001137, 001437, 000137).

Shelf Contamination Note: At a full fuse, Steel Blue Opalescent has the potential to deposit trace amounts of copper on the surface of the kilnshelf. These deposits may react with sulfur-bearing glasses in subsequent firings. Processes that require greater heatwork, such as pattern or flow bar techniques, can also lead to copper deposits. Such deposits may not be visible and can react even when the shelf has been properly scraped and reprimed or, alternatively, when used ThinFire has been removed and new ThinFire is applied. This type of contamination is impermanent and may be burned out/fired out over the course of subsequent firings. A contaminated shelf can be fired with glasses—other than sulfur-bearing glasses—and no reaction will take place. In our studios, we’ve observed the greatest contamination in subsequent firings with sulfur-bearing French Vanilla Opal (000137) and Spring Green Opal (000126). For a burnout firing, we recommend a rate of 300° F / hr to 1525º F, with a hold of 1:00.

Bullseye Compatible.

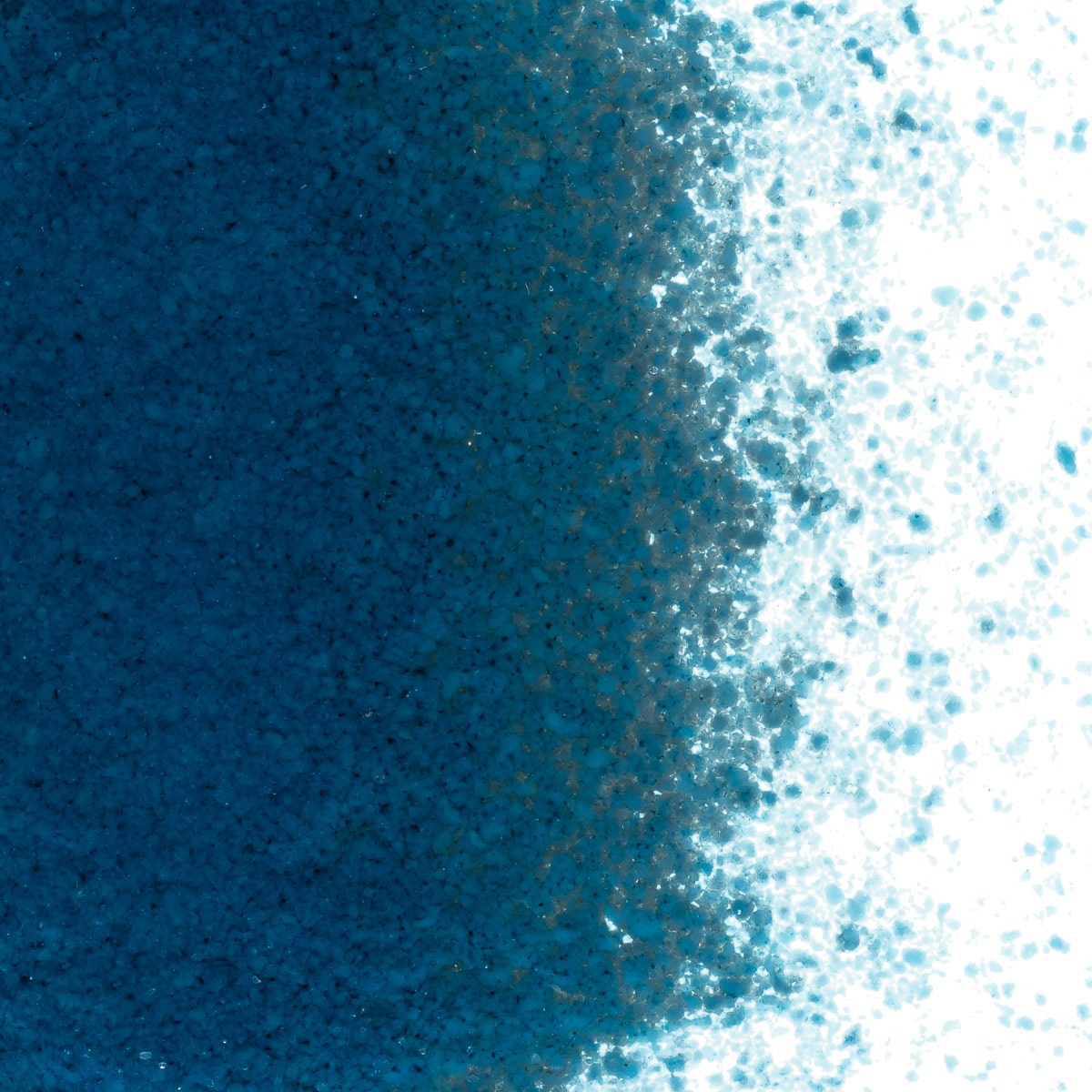

About 000146 Frit

Working Notes

See notes for Steel Blue sheet glass.

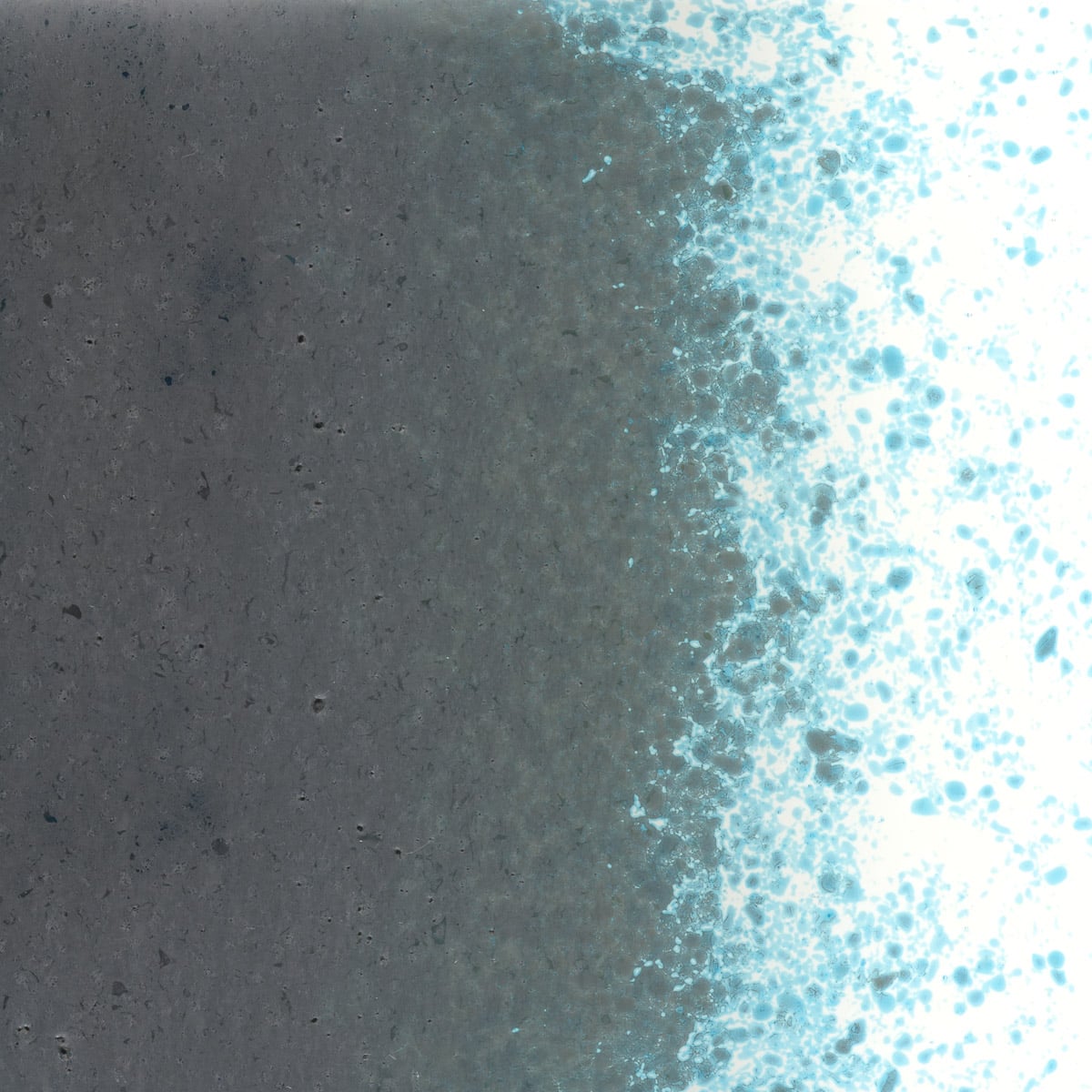

About 000146 Rod

Cold Characteristics

Opaque. Can have a dry surface.

Working Notes

Torch: Keep the glass blue by working it in a neutral flame throughout the process and keep it uniformly heated. Develop a matte metallic surface on this glass by forming the glass in a neutral flame; next change the flame to a reducing atmosphere by turning down the oxygen. At this point the surface should begin developing a metallic quality. Then turn off the oxygen completely, and build up a layer of carbon on the glass. Put the piece away in the annealing kiln with this carbon layer on it. Once removed from the kiln, the carbon is easily removed to expose a matte metallic surface. If you return the carbonized piece to a neutral flame, the metallic surface will disappear.

Kiln: Working properties and kilnformed characteristics are consistent with sheet glass. See sheet glass notes for this style.

About 000146 Stringer

Working Notes

As with sheet glass, Steel Blue Opalescent stringer may also develop a metallic gray film where exposed in the firing. This occurs most reliably when firing to lower tack fuse process temperatures. However, when performing this type of firing (such as to 1275°F), the metallic coating can prevent Steel Blue Opalescent stringer from fusing as completely compared to other opalescent styles. Stringers may appear “underfired” for the heatwork applied or may not adhere at all, especially when tack fusing Steel Blue Opalescent stringers to each other without contact to sheet glass. To learn more about this style, read Special Effects: Steel Blue Opalescent.

Kiln: Working properties and kilnformed characteristics are consistent with sheet glass. See sheet glass notes for this style.