Overview

Striker

This style may not reveal (strike to) its target color until fired.

Reactive Potential

Contains: Sulfur (S) / Selenium (Se)

May React With: Copper (Cu), Lead (Pb), and Silver (Ag)

Forms of Glass

Sheet Glass (-0030, -0050), Frit (-0001, -0002, -0003, -0008) and Rod (-0576)

Detailed Information

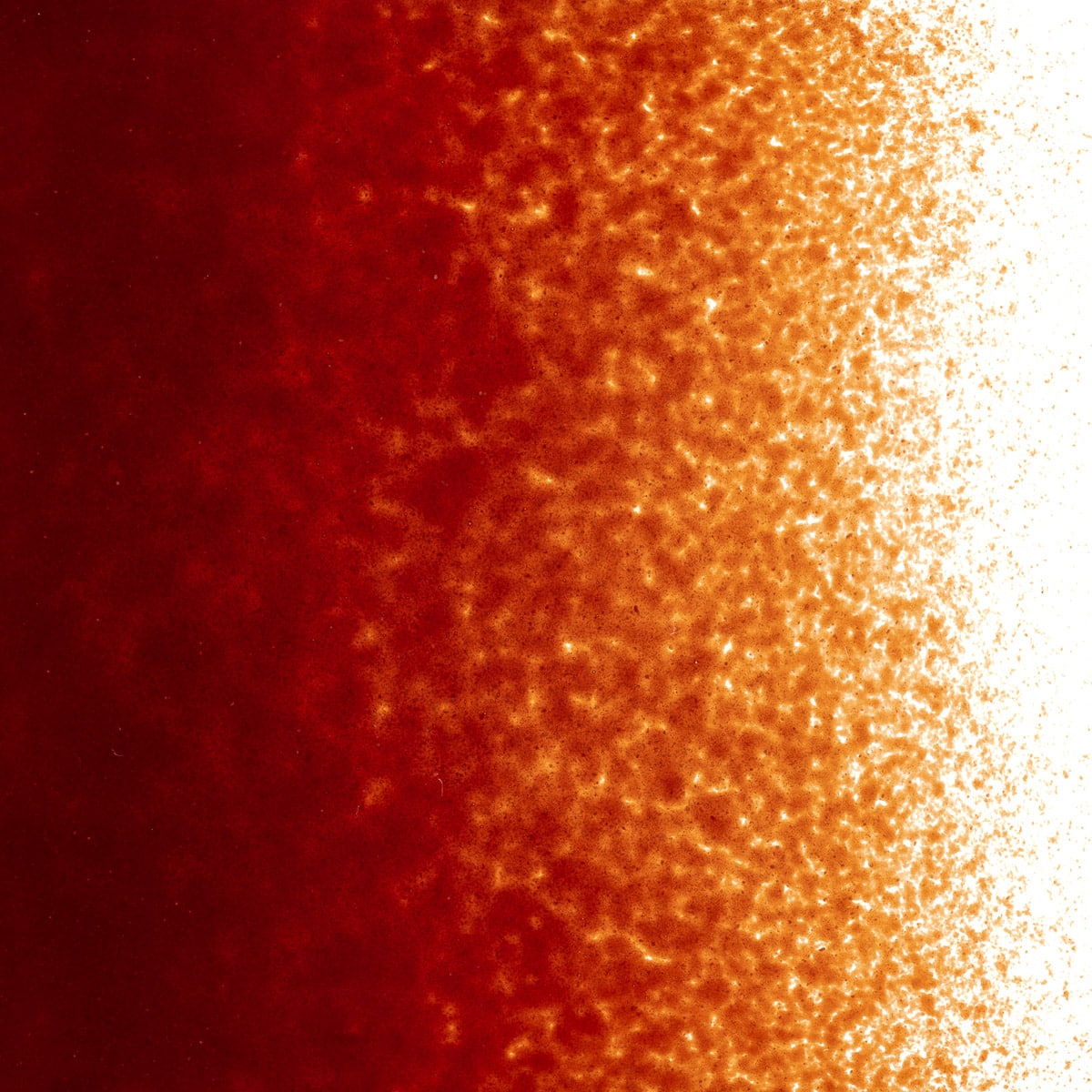

About 001322 Sheet Glass

Cold Characteristics

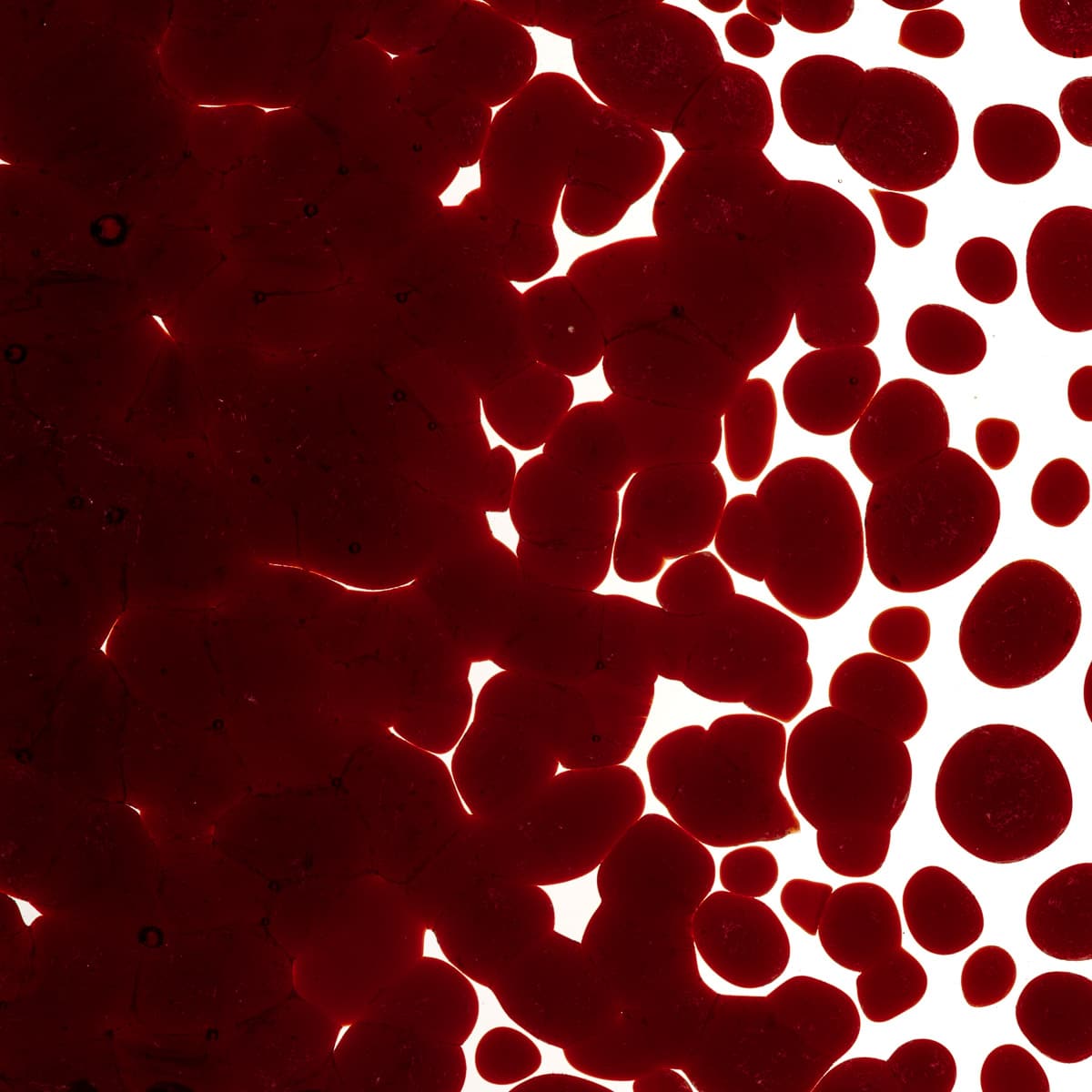

Appears light in color saturation with thin threads of color variation.

Working Notes

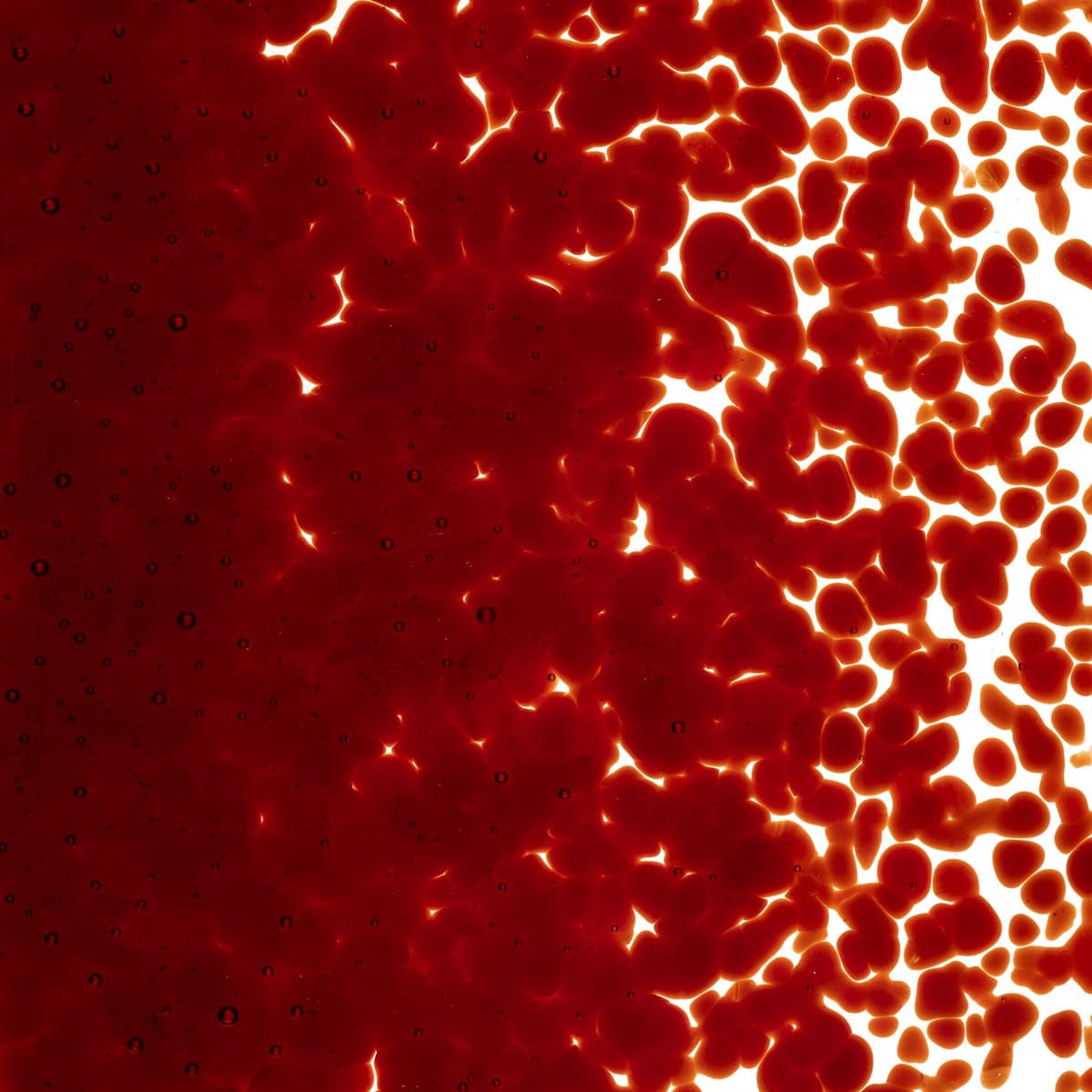

Matures to a more consistent color with deeper saturation. May contain subtle threads of darker color.

This style is not suitable for kilncasting because it can opalize and/or become incompatible when held at high temperatures for an extended period. It may also opalize and/or become incompatible in instances where processes exceed the parameters of the test for compatibility. Testing recommended when heatwork exceeds these parameters.

About 001322 Frit

Working Notes

This style is not suitable for kilncasting because it can opalize and/or become incompatible when held at high temperatures for a extended periods. It may also opalize and/or become incompatible in instances where processes exceed the parameters of the test for compatibility. Testing recommended when heatwork exceeds these parameters.

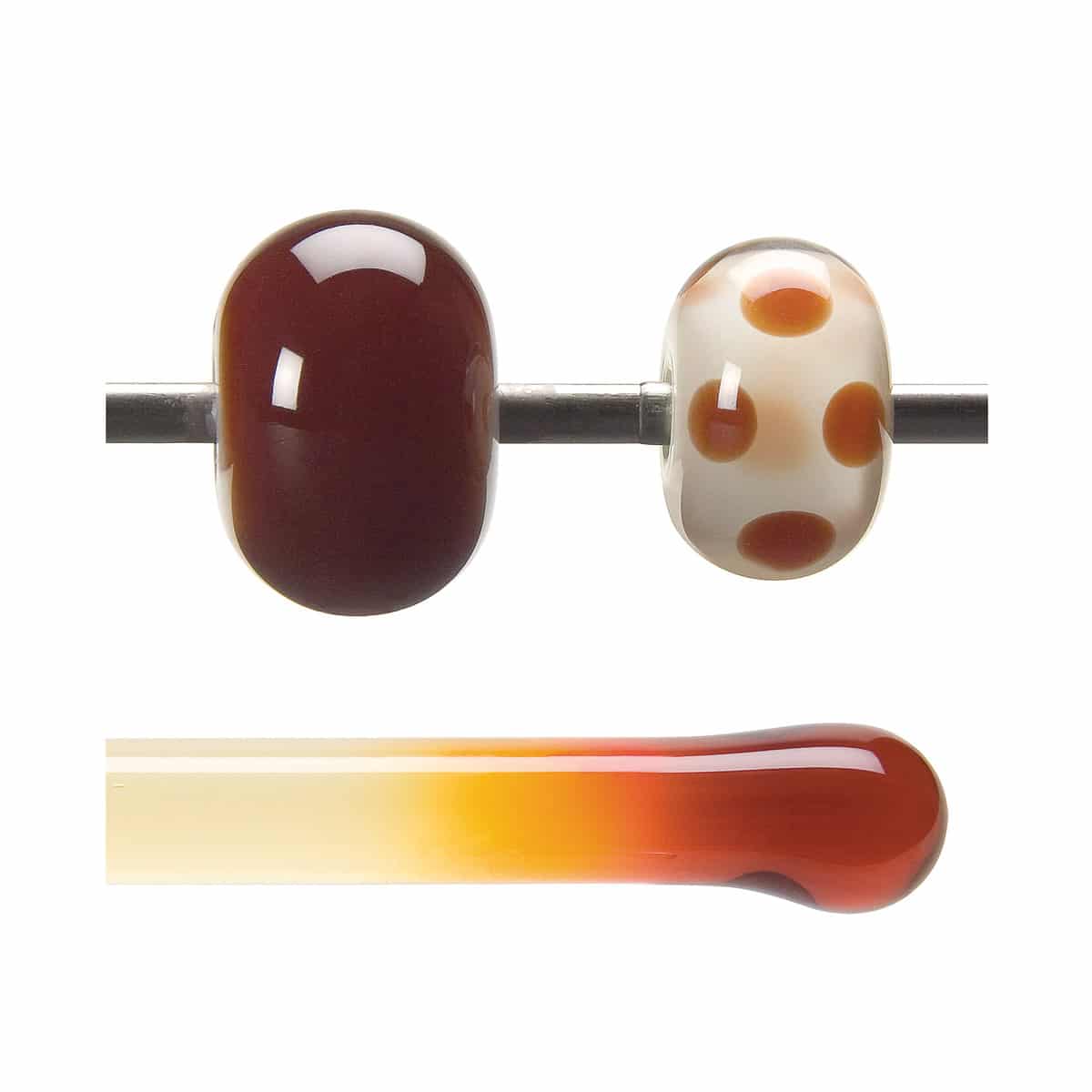

About 001322 Rod

Cold Characteristics

Pale transparent amber.

Working Notes

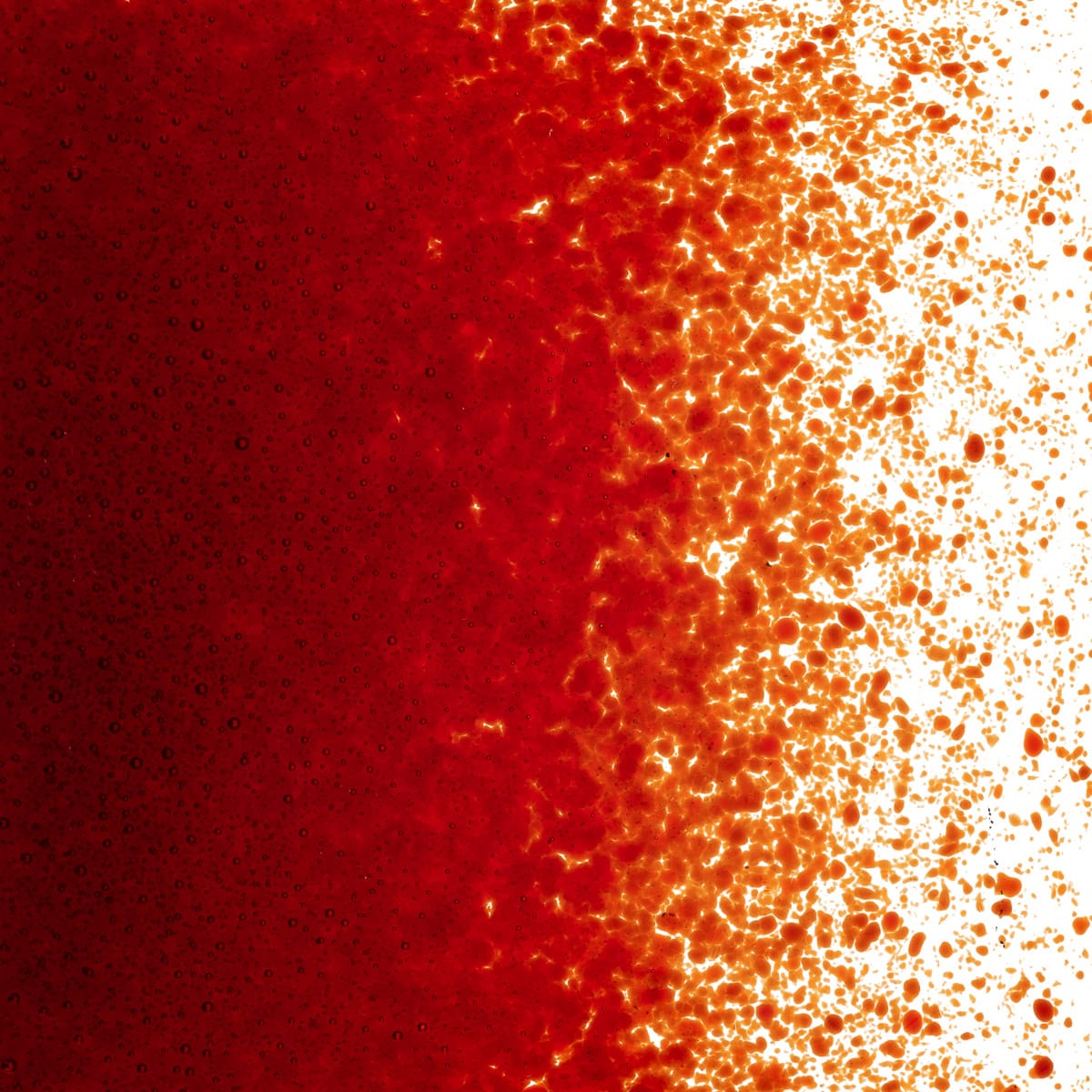

Torch: Strikes to a deep red in the flame and is rust colored in small amounts. Keep 001322-0576 transparent by using it in small amounts with minimal heatwork, or adding it near the end of the time in the flame. Before it is put into an annealing kiln, check that 001322-0576 has truly struck; it should appear very dark, almost black. If it is still light in color, gently cool and reheat the glass without bringing it to a molten state and watch for the glass to darken as it strikes. Labeling is advised because 001322-0576 looks very similar to Medium Amber Transparent (001137-0576).

Kiln: Hue and saturation may differ slightly when compared to sheet glass; a wider range is accepted due to changes that occur in the forming process.

This style is not suitable for kilncasting because it can opalize and/or become incompatible when held at high temperatures for a extended periods. It may also opalize and/or become incompatible in instances where processes exceed the parameters of the test for compatibility. Testing recommended when heatwork exceeds these parameters.