Author: Alex Davis

-

Pop Portraits’ Wood Stand

For many years, Bullseye has taught various ways to transfer images into colored glass through screen-printing techniques adapted to make use of our glass powders. Recently, we’ve incorporated Cricut vinyl…

-

Heart Making Station + Coupon Books

Glass is where the heart is! So visit the Heart Making Station at your local Bullseye Glass Resource Center and make yourself at home. No appointment needed. Prepared molds, glass,…

-

Bullseye Core Values + GMa Judy on Tik Tok

Serendipity. When the term was first coined in a letter between friends nearly 300 years ago, it referred to any happy discovery made possible through a special combination of chance…

-

Powder Power! Video Quick Tip

Learn the secret to minimizing large bubbles when fusing sheet glass to create smooth, flat fused glass.

-

Winter palettes in Bullseye glass, 4-6

More palettes — this time wintry — from the Bullseye Glass color catalog, accompanied with a bit of seasonal poetry. To acquire any of the colors displayed here in various…

-

Winter palettes in Bullseye glass, 1-3

More palettes — this time wintry — from the Bullseye Glass color catalog, accompanied with a bit of seasonal poetry. To acquire any of the colors displayed here in various…

-

Quagliata Book Signing & Retrospective

Book Signing at Bullseye Los Angeles and Judson Studios On Saturday, October 25, during a week of special events celebrating his exhibition at Forest Lawn Museum, Narcissus Quagliata had a…

-

Autumn palettes in Bullseye glass, 4-5

Here is more inspiration for fall palettes from the Bullseye Glass color catalog, accompanied with a bit of seasonal poetry. To acquire any of the colors displayed here in various…

-

Autumn palettes in Bullseye glass, 1-3

One of the simplest ways to spark inspiration is to play with likenesses—rhymes, chords, palettes. So here are a few palettes from Bullseye’s color catalog to draw from and play…

-

Working Glass 2024

Bullseye employees do a lot with Bullseye glass: they melt it, roll it, sell it, package it, ship it, and teach the world ways to work with it. But they…

-

Mold Tips: Using Bullseye Slumping Molds

Bullseye slumping molds are slipcast from a specially formulated clay body. They have an exceptionally smooth surface and accept kilnwash uniformly. If prepared with Bullseye Shelf Primer and handled properly,…

-

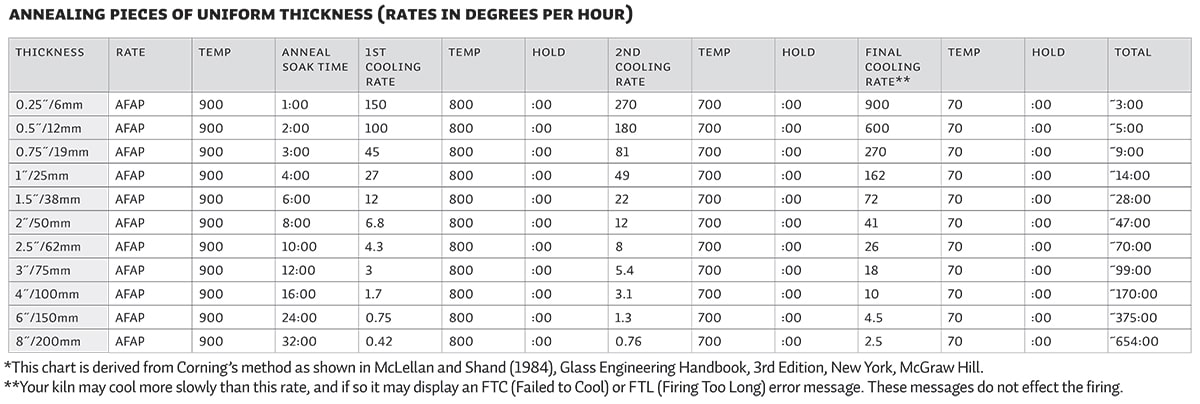

Annealing Thick Slabs

Fusing thick glass? You’ll want this chart! A conversion chart that helps you determine annealing times based on the thickness of your project. Shows both rates in time to temperature…

-

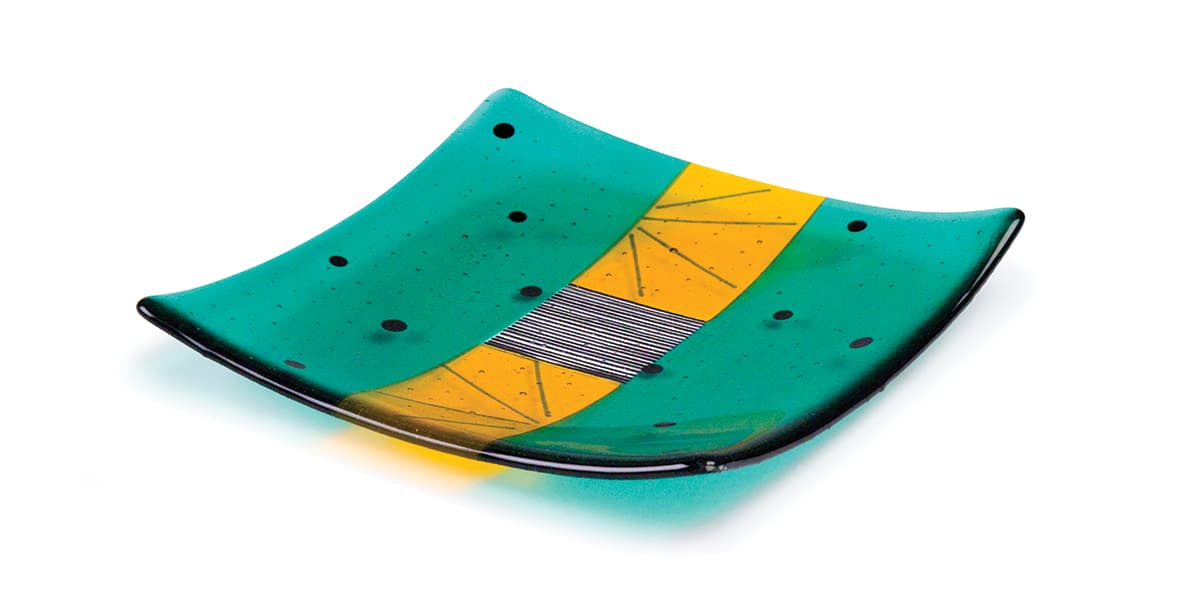

TipSheet 7: Platemaking Tips for Well-Crafted Vessels

Plates and platters are popular projects for both advanced and beginning kilnworkers, and platemaking is a perfect way to learn kilnforming’s two most frequently used methods: fusing and slumping. The…

-

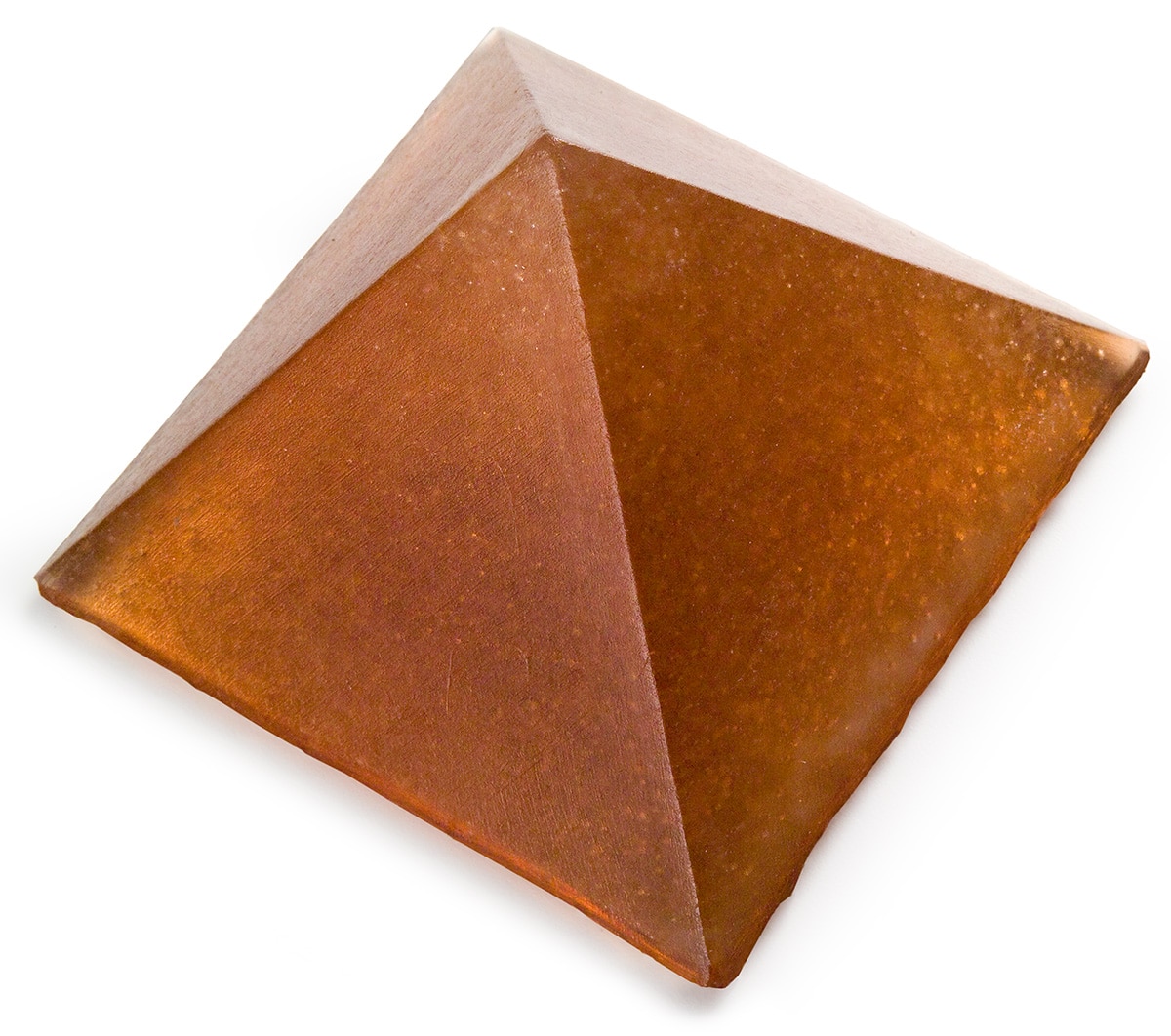

Mold Tips: Pyramid Casting Mold

Glass Selection It takes 2090 g (4.6 lbs) of glass to maximize the mold form, resulting in a pyramid that is 9.5 cm (3.75˝) tall. Any form of glass may…

-

Mold Tips: Heart Casting Mold

Glass Selection It takes 24 grams of glass to make a heart casting that is approximately 0.4˝(10 mm) thick (pictured). Examples shown were made with frit, but any form of…

-

Mold Tips: Deep Form Three-Step Process

Overview This process involves slumping a 15.5″-diameter circle over the course of three firings. (Note: always measure your mold before cutting your glass.) Each consecutive firing shapes the form, ultimately…

-

Mold Tips: Cone Bowl Molds

The following tips do not guarantee a uniform result. Because of the steep-sided nature of these molds, pieces may slump unevenly. Prior to slumping, prepare any of the Cone Bowl…

-

Mold Tips: Big Bowl

Note: The following tips do not guarantee a uniform result. Because of the steep-sided nature of this mold, pieces may slump unevenly. Slumping Options We have achieved the most consistent…

-

TipSheet 4: Designing Your Own Art Glass

Discover One of the Most Empowering Potentials of Glass Fusing Working with a palette of glass frit, powder, and stringers, you can create unique sheets of art glass to use…

-

TechNotes 2: The Vitrigraph Kiln

A Key Tool for Painting with Light Fused glass is frequently characterized by a cut-and-fit approach to design. Various shapes of colored glass are cut and fired to a base…

-

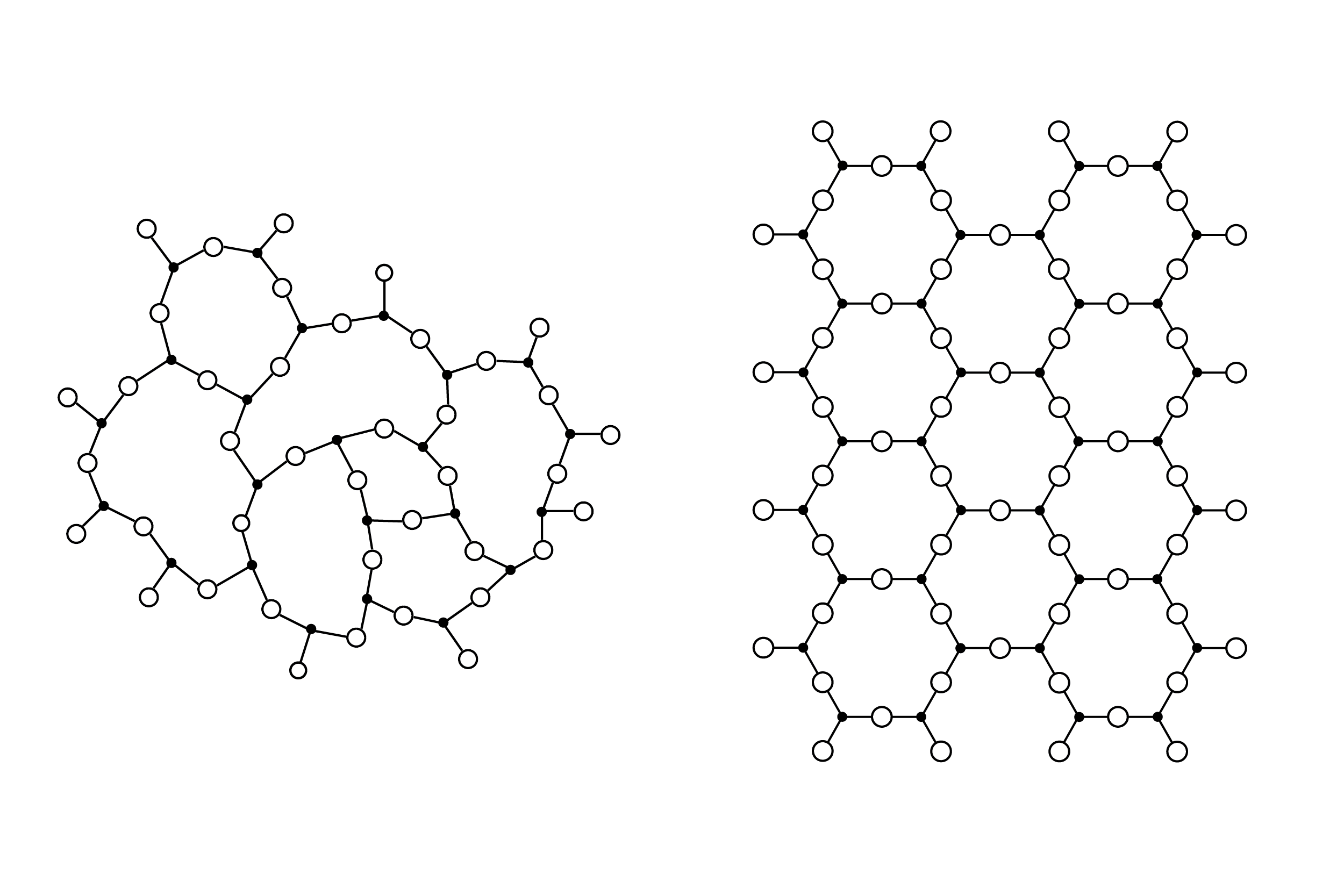

TechNotes 3: Compatibility of Glass

Why COE Isn’t the Whole Story A misunderstanding that the compatibility or “fit” of two glasses is solely a function of their expansion properties has led to an overemphasis on…

-

TechNotes 4: Heat & Glass

The Unique Nature of Glass—the Supercooled Liquid Glass is an amorphous material. Its molecules are not arranged in a regular, specific pattern, like those of a crystalline material (such as…

-

TechNotes 5: Volume & Bubble Control

Understanding Distortion & Trapped Air When Firing Bullseye Glass Two common problems encountered when fusing glass are distortions of shape and unanticipated bubbles. To avoid these effects—or to engineer them…

-

TechNotes 6: Preparing the Shelf System for a Large Kiln

Creating a Reliable Shelf System Creating large, finished glasswork that is flat, uniform, and well annealed is highly dependent upon having a reliable shelf system. An ideal shelf system for…

-

TechNotes 7: Monitoring Kiln Temperatures for Successful Annealing

The Importance of Achieving Uniform Cooling When kilnforming glass, especially largescale work, it is important to cool the glass uniformly throughout the annealing range. The temperature difference within the glass—from…

-

TipSheet 1: Kilncarving

A Simple Kilnforming Technique Developed by Rudi Gritsch “Kilncarving” is a term coined at Bullseye to describe a simple kilnforming process that achieves a bas relief, textured, or sculpted look…

-

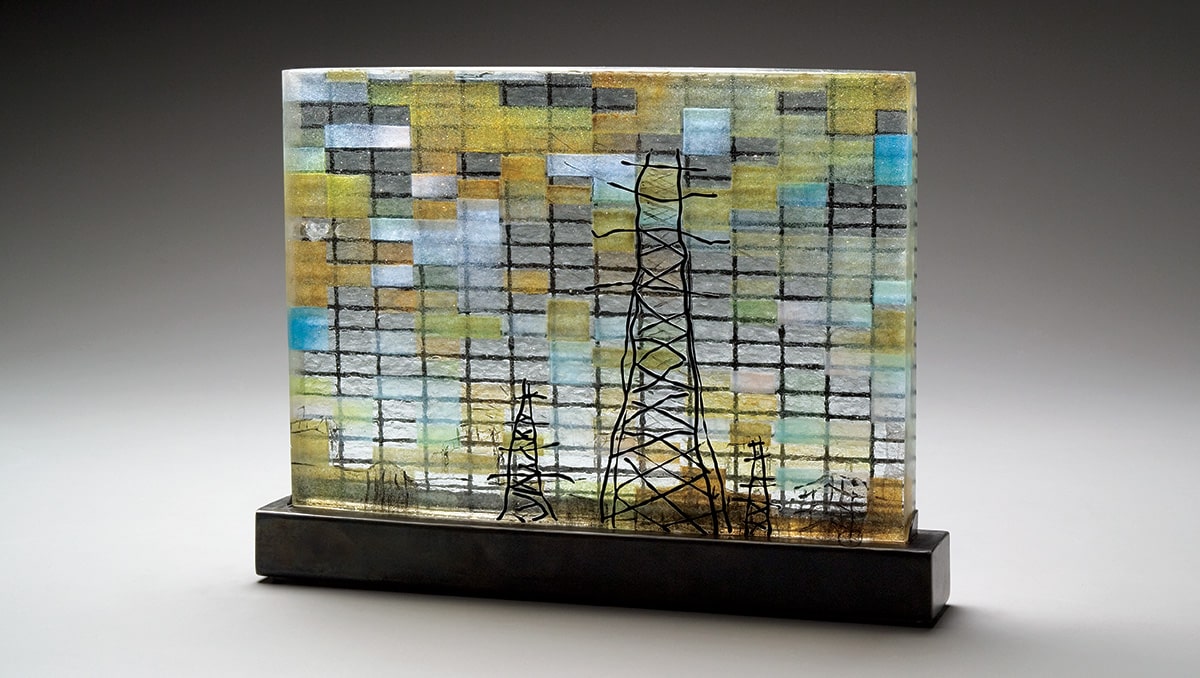

TipSheet 3: Working Deep

Stack Firing for Embedded Imagery This TipSheet will introduce you to ways to float imagery and color within thick blocks of clear glass. Historically, thick glass castings have resulted from…

-

12 Ways to Improve Your Glass Cutting

Basic Principles BUY THE BEST CUTTER YOU CAN AFFORD. If it helps you to cut accurately and comfortably, it will save you money in the long run. Look for a…

-

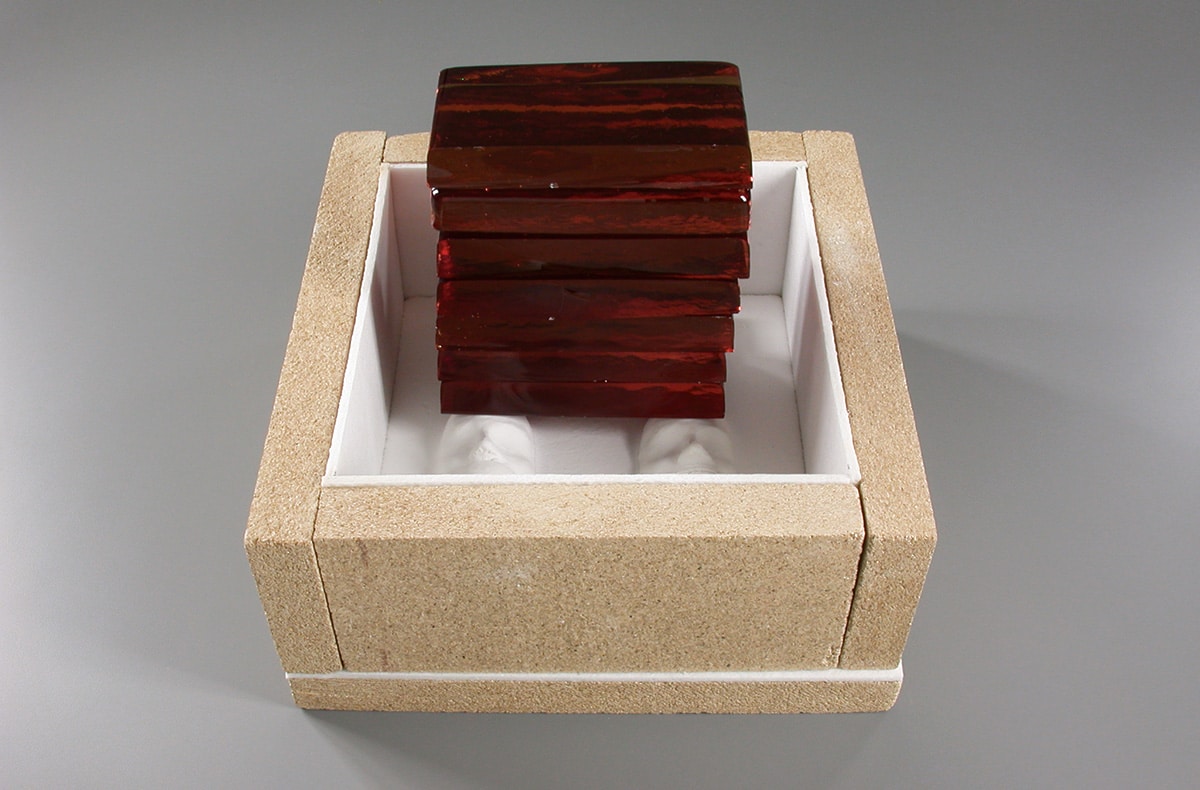

TipSheet 5: Bullseye Box Casting

Reverse-Relief Kilncasting in an Assembled Mold This TipSheet describes how to create a reverse-relief cast glass object with the optical clarity of a furnace casting, using plaster/silica design elements in…

-

TipSheet 6: Roll-Ups

A Brief History of the Roll-Up In 1993, Klaus Moje and Dante Marioni took part in the Connections project at the Bullseye factory in Portland. Together they explored the idea…

-

Safety in the Kiln-Glass Studio

General Considerations Good housekeeping and common sense go a long way toward ensuring safety in the kilnforming studio. Ventilate your studio well, keep dust to a minimum, and confine hazardous…

-

Glass Cleaning Basics

Simple & Essential Cleaning glass before firing it removes problem causing contaminants like glass-cutting fluid, oils, minerals, salts, dusts, fibers, sticker residues, fingerprints, and pen marks. If these substances are…

-

Glass Cutting Basics

Basic Principles A glass cutter does not saw glass. Rather, its cutting wheel “scores” the glass—creating a shallow fissure as it rolls across the surface. This fissure, or “scoreline,” breaks…

-

TechNotes 1: Knowing Your Kiln

Improve Kilnforming Results To achieve control in firing glass, it is necessary to understand how heat is distributed within the kiln you are using. Kiln heat is rarely even. Top-fired…

-

TipSheet 8: Basic Lost Wax Kilncasting

Unleash Your Unlimited Forms Lost wax kilncasting is a versatile method for making glass pieces in almost any form imaginable. The process involves creating a refractory mold around a wax…

-

Pre-Firing Your New Kiln

One Final Preparation Step Before using a new kiln for glass projects, you will need to pre-fire it. This burns out binders, moisture, and other residue left over from the…