Improve Kilnforming Results

To achieve control in firing glass, it is necessary to understand how heat is distributed within the kiln you are using. Kiln heat is rarely even. Top-fired kilns tend to be hotter in the center. Side-fired kilns are frequently hotter around the perimeter. The pyrometer reads only one point within the kiln chamber and may not give you an accurate indication of the heat treatment the glass is receiving. In working with a new kiln, making a few preliminary tests will help you to understand the kiln’s heating patterns and gain better control over your results.

TESTING THE “LOW END”

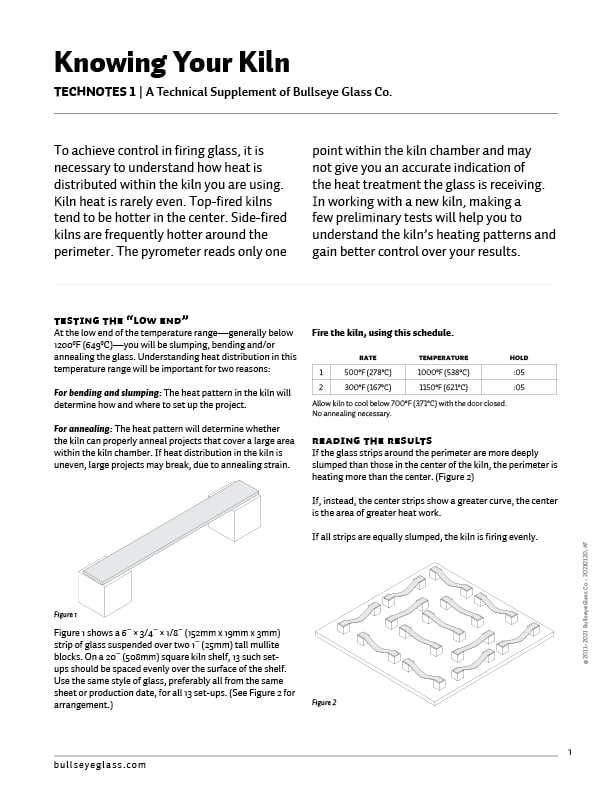

At the low end of the temperature range—generally below 1200ºF (649ºC)—you will be slumping, bending and/or annealing the glass. Understanding heat distribution in this temperature range will be important for two reasons: For bending and slumping: The heat pattern in the kiln will determine how and where to set up the project. For annealing: The heat pattern will determine whether the kiln can properly anneal projects that cover a large area within the kiln chamber. If heat distribution in the kiln is uneven, large projects may break, due to annealing strain…

CORRECTING FOR UNEVEN HEATING

If the test results indicate that your kiln is firing unevenly, you can choose from the following actions to correct the problem: 1. Use a slower firing cycle. 2. Reduce the size of the glass project relative to the size of the kiln shelf. For example, rather than covering the full 20˝ (508mm) width of a shelf with a piece, limit the dimensions of the piece to 14˝ (356mm). (Figure 3) 3. Reduce the size of the kiln shelf and raise it further off the kiln floor to allow greater heat circulation around the shelf and the piece. (Figure 4) If the test results indicate that the outer edges of the kiln are cooler than the center, try the following: 1. Insulate the edges of the glass piece with ceramic fiber paper, blanket, or board. This will slow down heat release from the edges. (Figure 5) 2. Create a perimeter wall of hard brick around the outer edges of the piece. Upon heating, the hard brick will absorb heat. Upon cooling, this absorbed heat will radiate back toward the glass and prevent its edges from cooling too rapidly. (Figure 6)