Note: The following tips do not guarantee a uniform result. Because of the steep-sided nature of this mold, pieces may slump unevenly.

Slumping Options

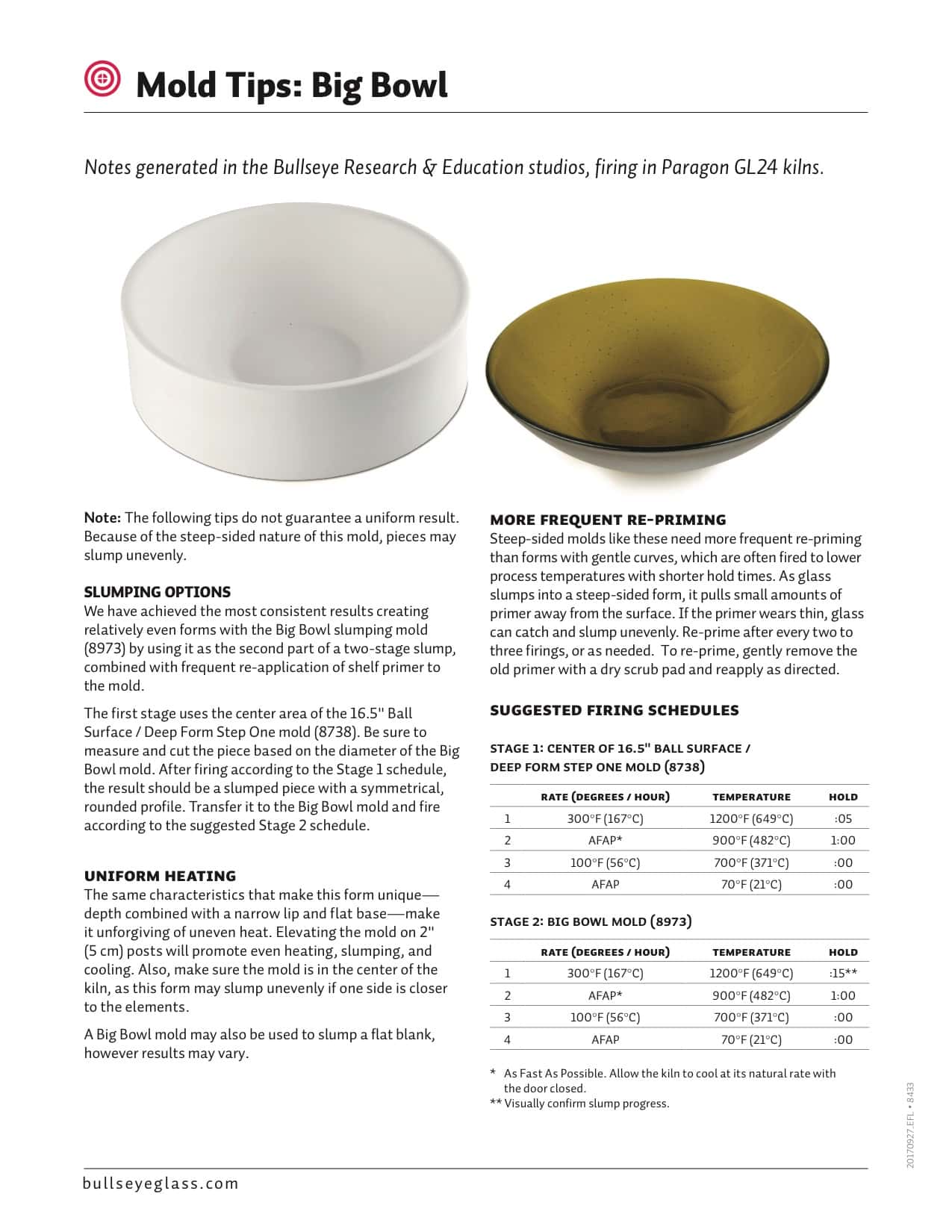

We have achieved the most consistent results creating relatively even forms with the Big Bowl slumping mold (8973) by using it as the second part of a two-stage slump, combined with frequent re-application of shelf primer to the mold. The first stage uses the center area of the 16.5″ Ball Surface / Deep Form Step One mold (8738). Be sure to measure and cut the piece based on the diameter of the Big Bowl mold. After firing according to the Stage 1 schedule, the result should be a slumped piece with a symmetrical, rounded profile. Transfer it to the Big Bowl mold and fire according to the suggested Stage 2 schedule.

Uniform Heating

The same characteristics that make this form unique— depth combined with a narrow lip and flat base—make it unforgiving of uneven heat. Elevating the mold on 2″ (5 cm) posts will promote even heating, slumping, and cooling. Also, make sure the mold is in the center of the kiln, as this form may slump unevenly if one side is closer to the elements. A Big Bowl mold may also be used to slump a flat blank, however results may vary.

More Frequent Re-Priming

Steep-sided molds like these need more frequent re-priming than forms with gentle curves, which are often fired to lower process temperatures with shorter hold times. As glass slumps into a steep-sided form, it pulls small amounts of primer away from the surface. If the primer wears thin, glass can catch and slump unevenly. Re-prime after every two to three firings, or as needed. To re-prime, gently remove the old primer with a dry scrub pad and reapply as directed.

Download the full article…