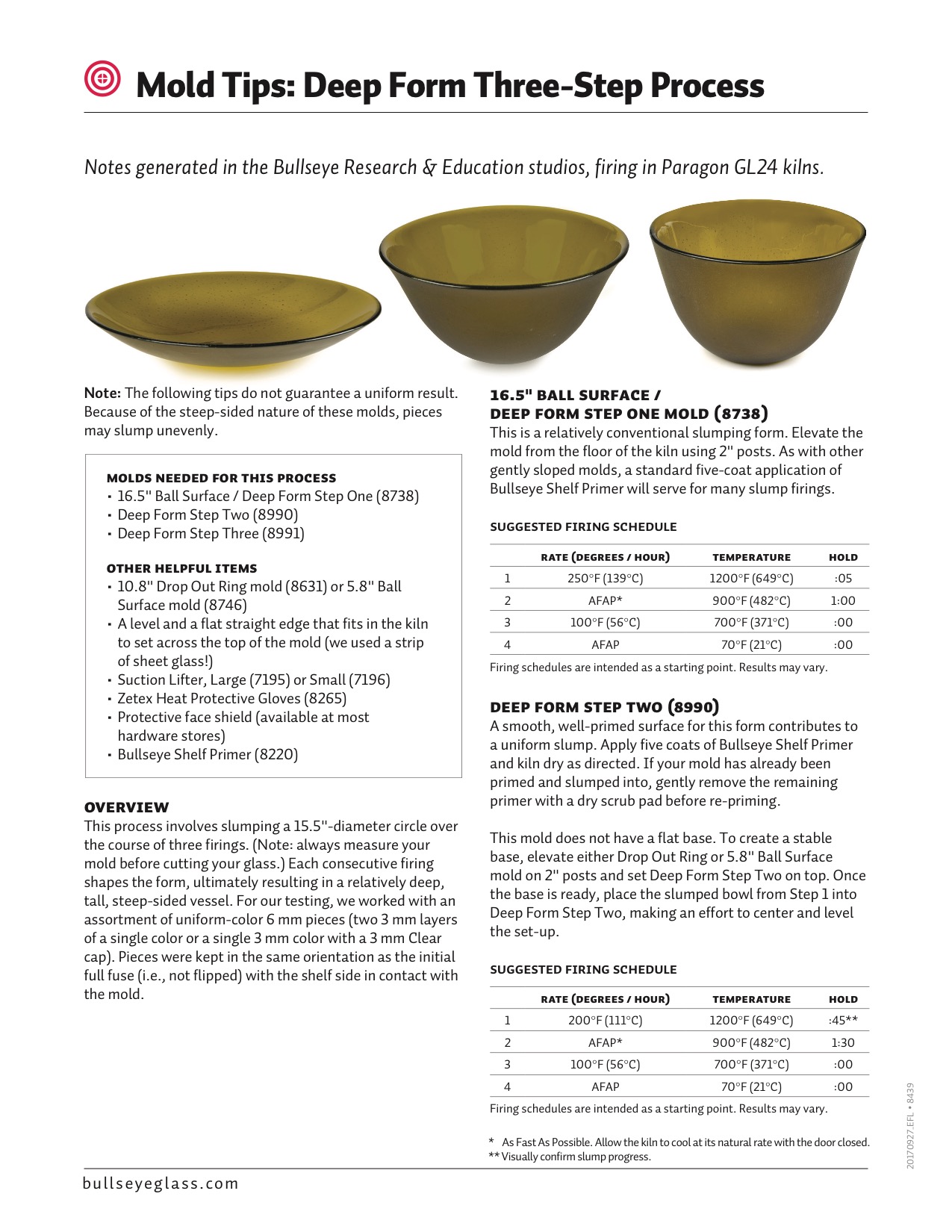

Overview

This process involves slumping a 15.5″-diameter circle over the course of three firings. (Note: always measure your mold before cutting your glass.) Each consecutive firing shapes the form, ultimately resulting in a relatively deep, tall, steep-sided vessel. For our testing, we worked with an assortment of uniform-color 6 mm pieces (two 3 mm layers of a single color or a single 3 mm color with a 3 mm Clear cap). Pieces were kept in the same orientation as the initial full fuse (i.e., not flipped) with the shelf side in contact with the mold.

Download the full article…