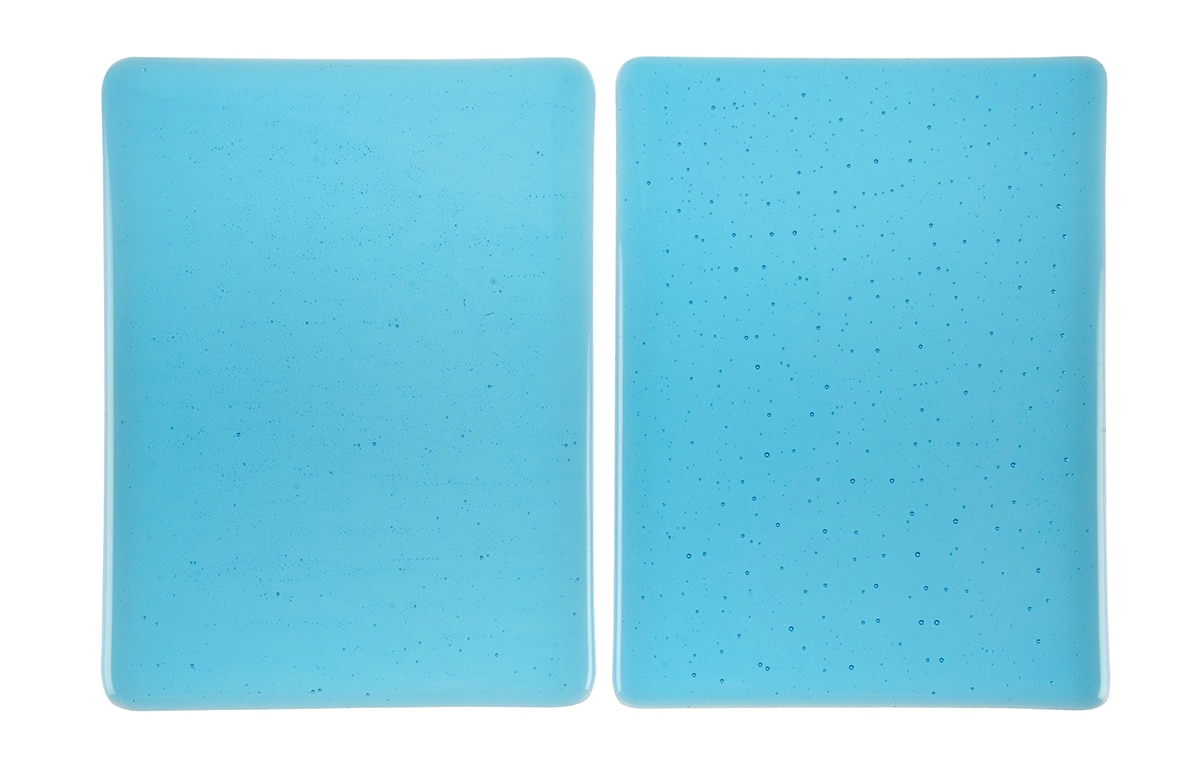

Want to minimize the look of bubbles in fused pieces?

This trick of the trade puts powder power in action, using a small amount of sifted clear powder between layers of sheet glass to help create a uniformly smooth, flat and seemingly bubble free effect.

See how it’s done in this video Quick Tip, where we make blanks for our in-person class Great Plates: Sandblasted! You can also read about the process below.

Sifting Station Set-up:

- A sheet of paper that is big enough to catch the overflow powder. A darker color will help make the powder visible if your base sheet is clear.

- Something to elevate your base sheet for easy transport to the kiln once the powder has been applied. Small condiment cups or old frit jar lids work great.

- Powder sifter

- Clear powder, 001101-0008 or 001401-0008

- Work in front of localized ventilation or wear a mask approved for particulates. (edit? link?)

Sift:

- Load your sifter with clear powder, leaving some room at the top.

- Hold the sifter about 18” above the sheet glass. Sift by tapping the back of the handle and moving the sifter to create a relatively thin, uniform coating of powder on the base sheet. A light application of powder is all that is needed and it’s okay if it’s notperfectly uniform.

- Look for a reflection on the sheet glass through the powder layer as it will help confirm that you’ve applied a good amount. Stop before the reflection has been fully obscured.

Fire:

- Move the base sheet to a prepared firing surface.

- Set the cap sheet in place gently to help keep the powder layer intact.

- Fire to a standard full fuse with a built-in bubble squeeze/hold around 1225°F/663°C on the way up to process temperature. There’s no need to modify the firing schedule based on this technique alone.

| Rate °/ hr | Temp | Hold |

| 300°F (167°C) | 1225°F (663°C) | 1:00 |

| 600°F (333°C) | 1490°F (810°C) | 0:10 |

Anneal and cool based on thickness.

Good to know:

- This technique is versatile and can be used when making various projects (i.e., transparent, opalescent, non-iridized). See a transparent example in QuickTip: Powder Power.

- We’ve found that this method is most predictable and effective when the base layer is a single sheet of glass.

- This approach traps more bubbles than firing without powder between the layers. The bubbles are typically smaller and less buoyant, so the fired works often have the appearance of having fewer bubbles.

- Using an open mesh screen (135tpi) is another way to apply powder quickly and uniformly, though often uses more material than is necessary. It’s a great method to keep in mind and could be just the thing for certain projects.