Reverse-Relief Kilncasting in an Assembled Mold

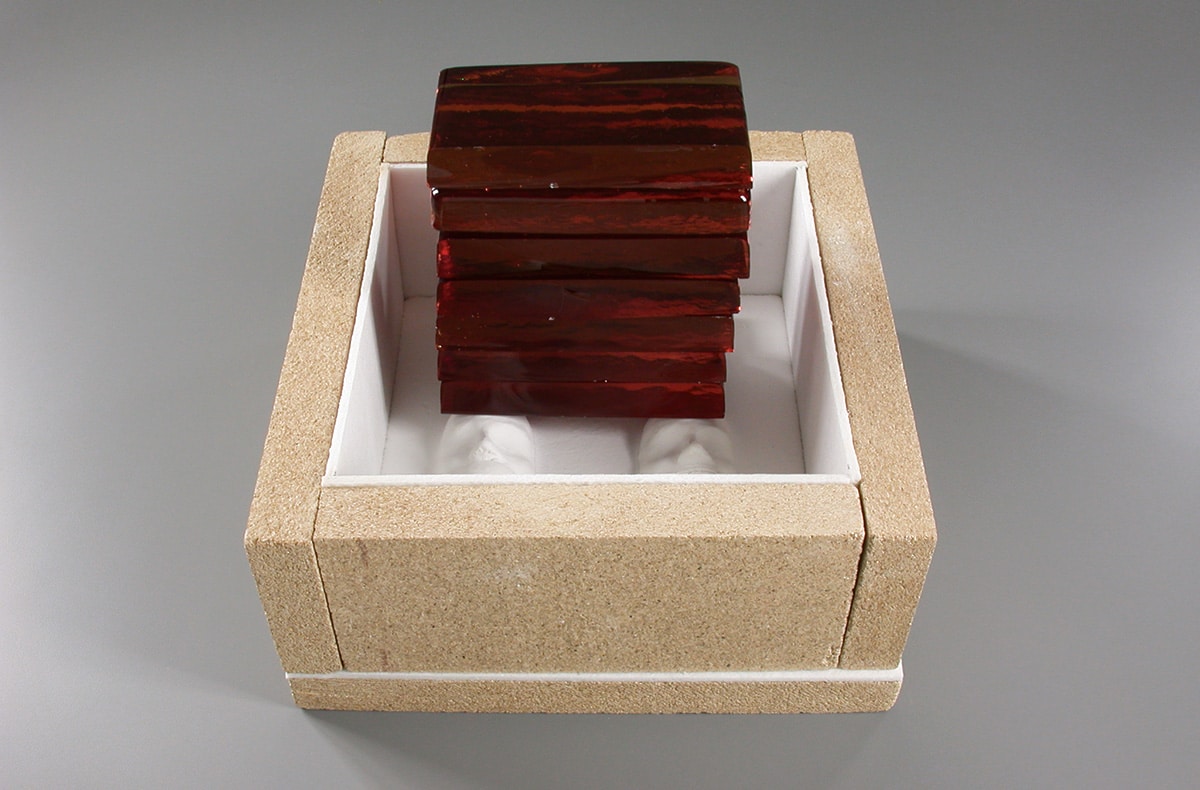

This TipSheet describes how to create a reverse-relief cast glass object with the optical clarity of a furnace casting, using plaster/silica design elements in an open-faced mold assembled from vermiculite board and other refractory materials. There are several advantages to this process:

• Less waste than traditional kilncasting processes

• The majority of the molds will be reusable

• Molds will be of uniform thickness, allowing for uniform heating and cooling

• Molds will not fail at casting temperature (one of the most common concerns in kilncasting and the reason there is such a boggling array of mold recipes in use)

• Cleaner and more predictable results than kilncasting in most of the traditional methods

• Extremely easy to repeat for the purpose of making editions or production work

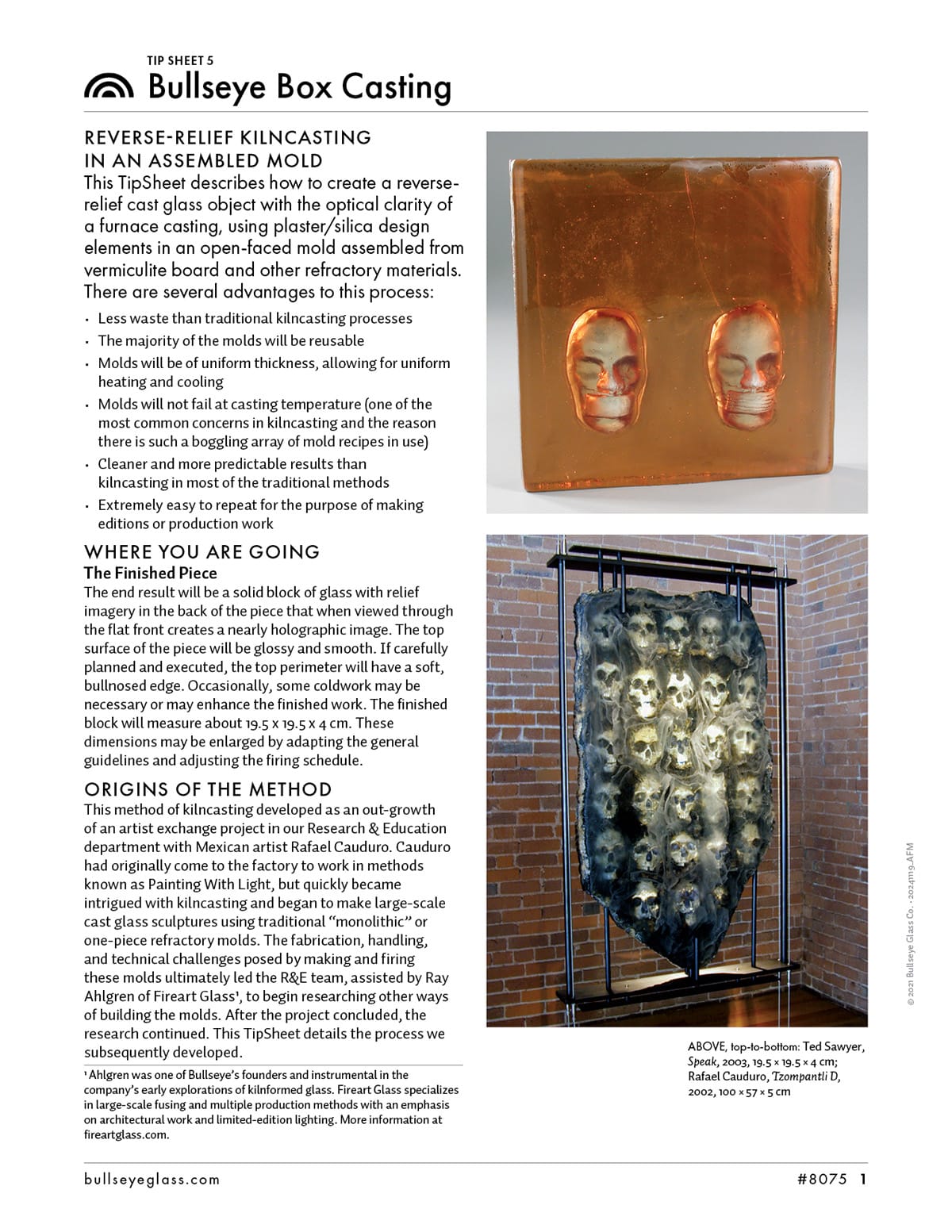

Where You Are Going: The Finished Piece

The end result will be a solid block of glass with relief imagery in the back of the piece that when viewed through the flat front creates a nearly holographic image. The top surface of the piece will be glossy and smooth. If carefully planned and executed, the top perimeter will have a soft, bullnosed edge. Occasionally, some coldwork may be necessary or may enhance the finished work. The finished block will measure about 19.5 x 19.5 x 4 cm. These dimensions may be enlarged by adapting the general guidelines and adjusting the firing schedule…